Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100090063158454

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Introduction

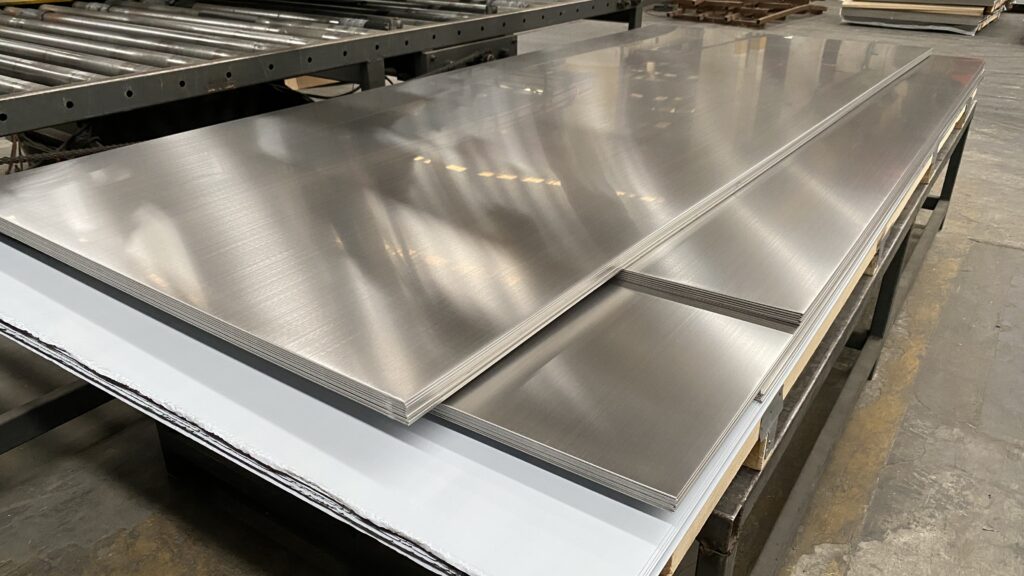

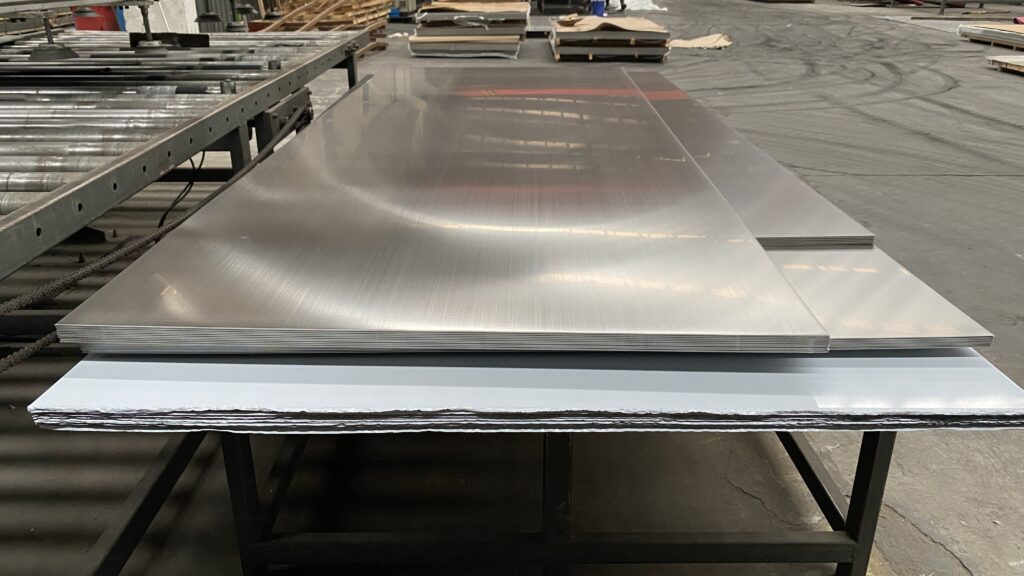

316 stainless steel material is one of the most versatile and widely used types of stainless steel due to its outstanding resistance to corrosion and durability. Known for its high levels of chromium, nickel, and molybdenum, this material offers enhanced performance in harsh environments and specialized applications. This article explores the unique properties of 316 stainless steel material, its diverse applications, and the many benefits it brings to industries around the world.

This blog post will feature a detailed analysis of 316 stainless steel material, including its chemical composition, properties, and a variety of applications. With a keyword density of at least 2%, we’ll also explore some tables to better illustrate its characteristics and uses.

Table of Contents

- Introduction

- What Is 316 Stainless Steel Material?

- Chemical Composition of 316 Stainless Steel Material

- Key Properties of 316 Stainless Steel Material

- Advantages of 316 Stainless Steel Material

- Applications of 316 Stainless Steel Material

- Table: Properties of 316 Stainless Steel Material

- Environmental Benefits of 316 Stainless Steel Material

- Maintenance Tips for 316 Stainless Steel Material

- Conclusion

- FAQs

What Is 316 Stainless Steel Material?

316 stainless steel material belongs to the austenitic family of stainless steels, containing approximately 16–18% chromium, 10–14% nickel, and 2–3% molybdenum. These elements create a stainless steel that’s especially resistant to corrosion, particularly from chlorides and acids. Known for its superior quality, 316 stainless steel material is widely used in applications where exposure to seawater, chemical environments, and extreme temperatures is common.

The addition of molybdenum distinguishes 316 stainless steel material from other types like 304 stainless steel, enhancing its performance in corrosive and saline environments.

Chemical Composition of 316 Stainless Steel Material

The chemical composition of 316 stainless steel material is key to its unique properties. Below is a breakdown of the typical chemical composition by percentage.

| Element | Percentage (%) |

|---|---|

| Chromium | 16.0 – 18.0 |

| Nickel | 10.0 – 14.0 |

| Molybdenum | 2.0 – 3.0 |

| Carbon | ≤ 0.08 |

| Manganese | ≤ 2.0 |

| Silicon | ≤ 1.0 |

| Phosphorus | ≤ 0.045 |

| Sulfur | ≤ 0.03 |

| Iron | Balance |

This composition enhances the material’s resistance to corrosion and allows it to maintain strength in high-stress environments.

Key Properties of 316 Stainless Steel Material

316 stainless steel material has numerous properties that make it valuable in various industries. Key properties include:

- Corrosion Resistance: Excellent resistance to pitting and crevice corrosion, especially in chloride-rich environments.

- High-Temperature Resistance: Performs well in high temperatures, making it ideal for industrial applications.

- Strength and Durability: Possesses high tensile strength and toughness, which allows it to withstand heavy stress and strain.

- Low Maintenance: Requires minimal upkeep due to its natural resistance to rust and degradation.

- Aesthetic Finish: Has a smooth, attractive appearance suitable for both structural and decorative applications.

Advantages of 316 Stainless Steel Material

1. Enhanced Corrosion Resistance

The molybdenum content in 316 stainless steel material provides significant resistance to corrosion, especially in chloride and acidic environments. This quality is crucial for industries like marine engineering and chemical processing.

2. High Durability

316 stainless steel material maintains its structure and performance even in challenging conditions. This durability ensures that structures and equipment last longer, reducing replacement and repair costs.

3. Temperature Resilience

316 stainless steel material remains stable in both high and low temperatures, making it suitable for applications in a range of climate and industrial conditions.

4. Ease of Fabrication

316 stainless steel material can be easily cut, welded, and fabricated, making it versatile for manufacturers and designers working on complex projects.

5. Eco-Friendly

Since 316 stainless steel material is recyclable, it contributes to sustainable practices in industries that prioritize environmental impact.

Applications of 316 Stainless Steel Material

Due to its resistance to corrosion and strength, 316 stainless steel material is applied across multiple industries, including:

- Marine Industry: Used in shipbuilding, marine fittings, and offshore oil rigs where resistance to seawater corrosion is essential.

- Chemical Processing: Ideal for equipment exposed to harsh chemicals, including storage tanks, valves, and pipes.

- Medical Equipment: Its biocompatibility and corrosion resistance make it suitable for surgical tools, implants, and other medical devices.

- Food Processing and Pharmaceuticals: Resistant to food acids and easy to sanitize, it’s widely used in food and pharmaceutical manufacturing.

- Construction and Architecture: Provides both strength and aesthetic appeal for outdoor structures, railings, and modern architecture.

Table: Properties of 316 Stainless Steel Material

| Property | Description |

|---|---|

| Corrosion Resistance | High, especially in chloride environments |

| Tensile Strength | 515 MPa |

| Yield Strength | 205 MPa |

| Elongation | 40% |

| Density | 8.0 g/cm³ |

| Thermal Conductivity | 16.3 W/m-K |

| Melting Point | 1371°C – 1399°C |

| Hardness | 217 HB (Brinell Hardness) |

| Weldability | Excellent |

| Machinability | Good, requires proper cutting tools and techniques |

These properties highlight the material’s suitability for both high-stress environments and precision applications.

Environmental Benefits of 316 Stainless Steel Material

316 stainless steel material is not only durable but also eco-friendly. Its recyclability allows it to be reused in various forms without losing its original properties. The production of 316 stainless steel material often includes recycled materials, which reduces the environmental impact of sourcing raw materials. This sustainability factor is increasingly important as industries focus on reducing carbon footprints.

Maintenance Tips for 316 Stainless Steel Material

To maintain 316 stainless steel material effectively:

- Regular Cleaning: Periodic washing with soap and water prevents buildup of dirt and chemicals.

- Avoid Harsh Chemicals: Use mild cleaning solutions to prevent damage to the protective layer.

- Inspect for Scratches: While 316 stainless steel material is durable, minor scratches should be checked and polished to avoid any corrosion risks.

- Rinse After Exposure to Saltwater: For outdoor or marine applications, rinsing with fresh water helps to maintain the material’s integrity.

With these maintenance practices, 316 stainless steel material can retain its appearance and performance for decades.

Conclusion

316 stainless steel material offers numerous benefits, from exceptional corrosion resistance to durability in extreme environments. Its unique properties, like high tensile strength and easy maintenance, make it valuable for applications across the marine, medical, chemical, and construction industries. With its environmentally friendly profile and long lifespan, 316 stainless steel material is an investment in both quality and sustainability.

FAQs

1. What makes 316 stainless steel material different from 304 stainless steel?

The key difference is the presence of molybdenum in 316 stainless steel material, which provides enhanced corrosion resistance, especially in chloride-rich environments.

2. Can 316 stainless steel material be used in high-temperature applications?

Yes, 316 stainless steel material has high-temperature resistance and maintains strength in both hot and cold conditions.

3. Is 316 stainless steel material suitable for food processing?

Absolutely. Its corrosion resistance and ease of cleaning make it an excellent choice for food processing equipment and environments.

4. How should I clean 316 stainless steel material in marine environments?

Rinse with fresh water regularly to remove salt and other contaminants that can accumulate on the surface, especially in coastal applications.

5. What is the lifespan of 316 stainless steel material?

With proper maintenance, 316 stainless steel material can last several decades, making it a long-lasting material for various industries.