Introduction

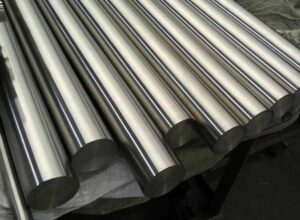

Stainless steel, renowned for its exceptional blend of mechanical strength and corrosion resistance, plays a pivotal role in various industries. Among the diverse array of stainless steel grades, 410 stainless steel emerges as a distinguished contender, celebrated for its unique composition and remarkable hardening capabilities. This article delves into the intricate world of quenching, exploring the potential of hardening 410 stainless steel through this transformative process.

The Essence of Quenching in Metallurgy

Quenching stands as a cornerstone of metallurgical alchemy, a process that transforms the very nature of metals through controlled heating and rapid cooling. The interplay between temperature, time, and cooling rates during quenching orchestrates dramatic changes in the microstructure, leading to a myriad of properties, including enhanced hardness and mechanical strength.

Quenching stands as a cornerstone of metallurgical alchemy, a process that transforms the very nature of metals through controlled heating and rapid cooling. The interplay between temperature, time, and cooling rates during quenching orchestrates dramatic changes in the microstructure, leading to a myriad of properties, including enhanced hardness and mechanical strength.

Decoding the Composition of 410 Stainless Steel

410 stainless steel’s composition sets the stage for its transformative journey through quenching. With a notable carbon content and a moderate infusion of chromium, this grade’s inherent attributes lay the groundwork for its exceptional response to heat treatment.

The Martensitic Marvel: 410 Stainless Steel

410 stainless steel is a member of the martensitic family, renowned for its ability to be hardened through heat treatment. Its microstructure undergoes a profound transformation during quenching, transitioning from the austenite phase to the coveted martensitic phase, characterized by heightened hardness and wear resistance.

Quenching: A Journey into Martensitic Transformation

Quenching 410 stainless steel involves heating it to a critical temperature, followed by rapid cooling in a quenching medium like oil or water. This rapid cooling halts the formation of equilibrium phases and triggers the formation of martensite, a crystalline structure that imparts exceptional hardness to the steel.

Critical Factors in Successful Quenching

Several factors contribute to the success of quenching 410 stainless steel:

- Quenching Medium: The choice of quenching medium influences the cooling rate, which in turn impacts the final hardness and microstructure.

- Critical Cooling Rate: Achieving the critical cooling rate ensures the transformation of austenite to martensite.

- Temperature Control: Precise temperature control during heating is essential to initiate the phase transformation.

Tempering: Finding the Balance Between Hardness and Toughness

While quenching endows 410 stainless steel with impressive hardness, it can also render the material excessively brittle. Tempering, a subsequent heat treatment step, alleviates this brittleness while maintaining enhanced mechanical properties. The tempering temperature and duration are carefully calibrated to strike the right balance between hardness and toughness.

Applications Showcasing Hardened 410 Stainless Steel

Hardened 410 stainless steel finds its place in various applications:

Hardened 410 stainless steel finds its place in various applications:

- Cutting Tools: Knives, blades, and cutting implements benefit from the enhanced hardness and wear resistance.

- Industrial Components: Bearings, valve parts, and pump shafts gain durability through the hardened properties.

- Medical Instruments: Surgical tools and dental equipment rely on the material’s hardness and corrosion resistance.

- Aerospace Parts: Components requiring strength and resistance to wear find a worthy candidate in hardened 410 stainless steel.

Unveiling Myths and FAQs About Quenching 410 Stainless Steel

Q1: Is quenching suitable for all stainless steel grades?

No, quenching’s effectiveness depends on the specific alloy composition and intended mechanical properties.

Q2: Can over-quenching make 410 stainless steel excessively brittle?

Yes, over-quenching can lead to excessive hardness and brittleness. Tempering after quenching restores ductility and toughness.

Q3: Can quenching improve corrosion resistance in 410 stainless steel?

Quenching primarily enhances hardness and mechanical properties. Corrosion resistance improvements are usually achieved through alloy composition adjustments.

Conclusion

Quenching serves as a metallurgical magic, transforming 410 stainless steel into a robust alloy endowed with exceptional hardness and mechanical strength. This transformative journey, fueled by the interplay of temperature and cooling rates, empowers engineers and designers to craft components that withstand the rigors of demanding applications. Through the fusion of science and craftsmanship, quenching lends 410 stainless steel its formidable character, weaving it into the tapestry of materials that shape the modern world.