Introduction

In today’s fast-paced industrial landscape, the demand for durable, corrosion-resistant materials is paramount. Among these, 316 stainless steel bars stand out for their exceptional properties, making them indispensable across various sectors. From manufacturing to construction, this versatile alloy finds innovative applications that drive efficiency, reliability, and sustainability.

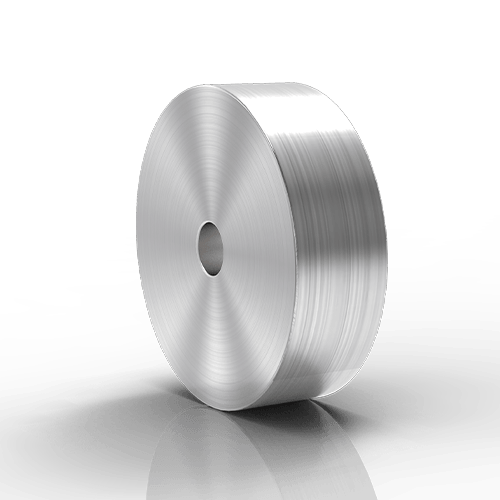

Properties of 316 Stainless Steel Bars

316 stainless steel possess a unique combination of mechanical properties and corrosion resistance, making them ideal for diverse applications. With a minimum of 10% nickel content, this alloy exhibits excellent resistance to corrosion, particularly in acidic and chloride environments. Moreover, its molybdenum content enhances its pitting and crevice corrosion resistance, expanding its utility in challenging conditions.

Innovative Applications

- Marine EngineeringIn marine engineering, where exposure to corrosive saltwater is inevitable, 316 stainless steel bars excel. These bars are used in shipbuilding, offshore platforms, and marine equipment due to their exceptional corrosion resistance and durability. From ship hulls to critical components like propeller shafts and fasteners, 316 stainless steel ensures longevity and performance in harsh maritime environments.

- Medical DevicesThe medical industry relies on materials that guarantee hygiene, strength, and biocompatibility. 316 stainless steel bars find extensive use in medical devices and equipment, such as surgical instruments, implants, and orthodontic appliances. Their corrosion resistance, non-reactivity, and sterilizability make them indispensable in healthcare, ensuring patient safety and device reliability.

- Food ProcessingHygiene and corrosion resistance are paramount in food processing environments to maintain product quality and safety. 316 stainless steel are widely employed in food processing equipment, including conveyors, tanks, and storage containers. Their smooth surface finish, resistance to corrosion from food acids, and ease of cleaning ensure compliance with stringent sanitary standards while facilitating efficient food production processes.

- Architectural StructuresIn architectural applications, aesthetics, durability, and sustainability are key considerations. 316 stainless steel bars are utilized in architectural structures, facades, and interior designs for their sleek appearance, corrosion resistance, and structural strength. From iconic landmarks to contemporary building designs, this alloy offers architects and designers the freedom to create innovative and enduring structures.

- Automotive IndustryThe automotive industry demands materials that can withstand harsh operating conditions while reducing weight and improving fuel efficiency. 316 stainless steel bars find application in automotive components such as exhaust systems, fuel tanks, and structural frames. Their corrosion resistance, high-temperature strength, and formability contribute to enhanced performance, longevity, and sustainability in vehicles.

Case Studies: Applications in Action

| Industry | Application | Benefits |

|---|---|---|

| Marine Engineering | Shipbuilding | Corrosion resistance, longevity |

| Medical Devices | Surgical Instruments | Biocompatibility, sterilizability |

| Food Processing | Conveyors | Hygiene, ease of cleaning |

| Architectural Structures | Facades | Aesthetics, durability |

| Automotive Industry | Exhaust Systems | Corrosion resistance, weight reduction |

Conclusion

The widespread adoption of 316 stainless steel bars across industries underscores their exceptional properties and versatility. From marine engineering to automotive applications, these bars offer unmatched corrosion resistance, strength, and reliability, driving innovation and efficiency in diverse sectors. As industries continue to evolve, the demand for high-performance materials like 316 stainless steel bars is expected to grow, shaping a sustainable and resilient future.

FAQ

Q:What distinguishes 316 stainless steel bars from other stainless steel alloys?

A:316 stainless steel bars contain molybdenum, enhancing their corrosion resistance, particularly in chloride environments.They exhibit superior strength and toughness compared to other stainless steel alloys, making them suitable for a wide range of applications.

Q:Can 316 stainless steel bars be welded?

A:Yes, 316 stainless steel bars are readily weldable using conventional welding techniques. However, proper welding procedures and post-weld treatments are necessary to maintain corrosion resistance and mechanical properties.

Q:Are there any limitations to the use of 316 stainless steel bars?

A:While 316 stainless steel bars offer excellent corrosion resistance, they may not be suitable for highly acidic or high-temperature environments. In such cases, alternative materials or specialized coatings may be required.

Q:What maintenance is required for 316 stainless steel bars in marine environments?

A:Regular cleaning and inspection are essential to prevent the accumulation of marine fouling and corrosion. Additionally, applying protective coatings or inhibitors can prolong the lifespan of 316 stainless steel bars in marine applications.