Introduction

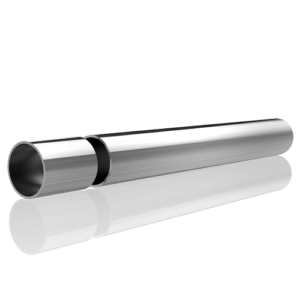

Stainless steel 304 pipes stand as stalwarts in the realm of piping materials, renowned for their versatility, durability, and corrosion resistance. In this blog post, we delve into the intricacies of stainless steel 304 pipes, exploring their strengths, applications, and maintenance tips.

Understanding Stainless Steel 304 Pipes

Stainless steel 304, a grade renowned for its composition of 18% chromium and 8% nickel, boasts exceptional corrosion resistance properties, making it an ideal choice for various industrial and domestic applications. These pipes are manufactured using a combination of modern technology and metallurgical expertise, ensuring uniformity and reliability in performance.

Applications of Stainless Steel 304 Pipes

Stainless steel 304 pipes find extensive applications across diverse industries due to their exceptional properties. Some notable applications include:

- Construction: SS 304 pipes are widely used in construction for plumbing, structural support, and architectural applications.

- Oil and Gas: These pipes are utilized in the oil and gas industry for transporting corrosive fluids and gases.

- Food Processing: Due to their hygienic properties, SS 304 pipes are prevalent in food processing plants for conveying food products and fluids.

- Chemical Processing: The corrosion resistance of stainless steel 304 makes it suitable for chemical processing plants where exposure to harsh chemicals is common.

- Automotive: SS 304 pipes are used in exhaust systems and other automotive applications due to their resistance to high temperatures and corrosion.

Maintenance and Care Tips

While SS 304 pipes are renowned for their durability, proper maintenance is essential to maximize their lifespan. Here are some maintenance tips:

- Regular cleaning with mild detergent and water to remove dirt and debris.

- Avoid abrasive cleaners and scouring pads that can scratch the surface.

- Periodic inspection for signs of corrosion or damage and prompt repairs if necessary.

- Application of protective coatings for added corrosion resistance in harsh environments.

Strengths of Stainless Steel 304 Pipes

Stainless steel 304 pipes exhibit a myriad of strengths, making them a preferred choice across industries. Below are some key strengths:

| Strengths | Description |

|---|---|

| Corrosion Resistance | With high chromium content, SS 304 pipes resist corrosion from a wide range of chemicals and environments. |

| Strength and Durability | SS 304 pipes offer excellent strength and durability, ensuring longevity in various applications. |

| Temperature Resistance | These pipes maintain their structural integrity at both high and low temperatures, making them suitable for extreme conditions. |

| Hygienic Properties | SS 304 is non-porous, making it easy to clean and ideal for applications requiring high levels of hygiene, such as in the food and pharmaceutical industries. |

Conclusion

Stainless steel 304 pipes stand as a testament to the ingenuity of modern metallurgy, offering unparalleled strength, durability, and corrosion resistance. From construction to chemical processing, these pipes find myriad applications, ensuring the seamless flow of fluids and gases across industries. By understanding their strengths and adopting proper maintenance practices, users can harness the full potential of stainless steel 304 pipes for years to come.

FAQ

Q: What is the difference between stainless steel 304 and 316 pipes?

A: While both grades offer excellent corrosion resistance, 316 stainless steel contains molybdenum, providing enhanced resistance to chloride corrosion, making it suitable for marine environments and applications involving exposure to saltwater.

Q: Can stainless steel 304 pipes be welded?

A: Yes, stainless steel 304 pipes are readily weldable using common welding techniques such as TIG, MIG, and stick welding. However, proper welding procedures should be followed to avoid issues such as sensitization and intergranular corrosion.

Q: Are stainless steel 304 pipes suitable for high-pressure applications?

A: Yes, stainless steel 304 pipes exhibit high strength and can withstand high pressures, making them suitable for various high-pressure applications such as hydraulic systems and industrial processes.

Q: How do I identify stainless steel 304 pipes?

A: Stainless steel 304 pipes are typically labeled or stamped with the grade designation. Additionally, their non-magnetic properties and distinctive bright, silvery finish can help differentiate them from other materials.

In conclusion, stainless steel 304 pipes offer a winning combination of strength, versatility, and corrosion resistance, making them indispensable in numerous industries. By leveraging their strengths and adhering to proper maintenance practices, users can rely on these pipes for efficient and reliable performance in a wide range of applications.