Introduction

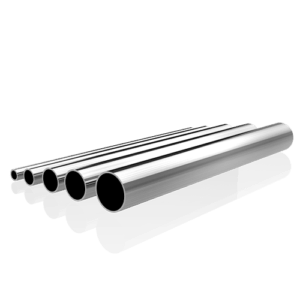

When it comes to selecting the right material for various applications, 304 stainless steel tubing sizes play a crucial role in ensuring both functionality and durability. Known for its excellent resistance to corrosion and high strength, 304 stainless steel is a popular choice across many industries. This comprehensive guide will delve into the details of 304 stainless steel tubing sizes, types, applications, and maintenance, helping you make well-informed decisions for your projects.

What is 304 Stainless Steel Tubing?

304 stainless steel tubing is manufactured from 304 stainless steel, an alloy that includes chromium and nickel, providing superior corrosion resistance and strength. This type of tubing is commonly used in a variety of applications due to its durability and versatility.

Key Properties of 304 Stainless Steel Tubing

- Corrosion Resistance: 304 stainless steel tubing sizes offer excellent protection against rust and corrosion, making it ideal for outdoor and industrial applications.

- Strength: The alloy’s high tensile strength ensures that tubing can withstand significant stress and pressure.

- Formability: It is easy to weld, machine, and fabricate, enhancing its usability across various projects.

- Aesthetic Appeal: With a smooth and shiny finish, 304 stainless steel tubing sizes contribute to a polished and professional appearance.

Types of 304 Stainless Steel Tubing

Understanding the types of 304 stainless steel tubing sizes can help you select the right option for your needs. Here are the common types:

Seamless Tubing

Seamless tubing is produced without welding, ensuring uniform strength and thickness. It is suitable for high-pressure applications where reliability is essential.

Welded Tubing

Welded tubing is made by welding stainless steel strips into a tubular shape. It is cost-effective and used in applications where the highest strength is not required.

Drawn Over Mandrel (DOM) Tubing

DOM tubing is a type of welded tubing that has been drawn through a die to improve its mechanical properties and dimensional accuracy. It provides enhanced strength and is used in demanding applications.

Electropolished Tubing

Electropolished tubing has undergone an additional finishing process to improve its surface smoothness and corrosion resistance. It is commonly used in sanitary applications and environments requiring high cleanliness.

Common 304 Stainless Steel Tubing Sizes

Choosing the right 304 stainless steel tubing sizes is critical for ensuring that the tubing fits the application properly. Tubing sizes are typically specified by their outer diameter (OD) and wall thickness. Here are some common sizes and their applications:

Common Tubing Sizes and Their Uses

| Size (OD x Wall Thickness) | Application | Typical Use |

|---|---|---|

| 1/2″ x 0.065″ | Small-scale applications | Automotive parts, small machinery |

| 1″ x 0.083″ | Medium-scale applications | Structural supports, railings |

| 2″ x 0.120″ | Larger applications | Industrial frames, handrails |

| 4″ x 0.250″ | Heavy-duty applications | Large piping, structural components |

Tubing Sizes by Schedule

Another way to specify 304 stainless steel tubing sizes is by schedule number, which indicates the wall thickness. Here are some common schedules:

| Schedule Number | Wall Thickness (in.) | Typical Applications |

|---|---|---|

| Schedule 10 | 0.065 | Light-duty applications |

| Schedule 40 | 0.083 | General-purpose use |

| Schedule 80 | 0.119 | High-pressure systems |

How to Choose the Right 304 Stainless Steel Tubing Sizes

Selecting the appropriate 304 stainless steel tubing sizes involves considering several factors:

Application Requirements

Determine the requirements of your application, such as pressure, temperature, and exposure conditions. For high-pressure or critical uses, choose seamless or DOM tubing with the appropriate 304 stainless steel tubing sizes.

Size and Dimensions

Ensure that the 304 stainless steel tubing sizes match the specifications needed for your project. Accurate OD and wall thickness are essential for proper fit and performance.

Surface Finish

Select between standard and electropolished tubing based on the cleanliness and aesthetic needs of your application. Electropolished tubing is especially beneficial for sanitary or high-visibility uses.

Standards and Compliance

Verify that the chosen 304 stainless steel tubing sizes comply with industry standards and regulations, such as ASTM, ISO, and ASME.

Comparing 304 Stainless Steel Tubing with Other Materials

To make an informed choice, compare 304 stainless steel tubing sizes with other materials:

| Material | Corrosion Resistance | Strength | Cost | Applications |

|---|---|---|---|---|

| 304 Stainless Steel | Excellent | High | Moderate | General use, food processing, medical equipment |

| Carbon Steel | Moderate | High | Low | Construction, automotive |

| Aluminum | Good | Moderate | Low to Moderate | Lightweight structures, aerospace |

| Plastic | Variable | Low to Moderate | Low | Chemical handling, plumbing |

Maintenance and Care of 304 Stainless Steel Tubing

Proper maintenance of 304 stainless steel tubing sizes ensures longevity and performance:

Regular Cleaning

Clean tubing regularly to remove contaminants. Use mild detergents and avoid abrasive materials that could damage the surface.

Inspection

Periodically inspect for signs of wear, corrosion, or damage. Check for leaks and structural integrity, especially in high-pressure environments.

Proper Storage

Store tubing in a dry, clean place to prevent exposure to corrosive elements. Use protective covers if necessary to shield from environmental factors.

Conclusion

304 stainless steel tubing sizes are a critical factor in selecting the right tubing for various applications. By understanding the types, sizes, and applications of 304 stainless steel tubing, you can ensure that you choose the best option for your specific needs. Whether you require tubing for industrial, residential, or specialized applications, proper selection and maintenance of 304 stainless steel tubing sizes will help achieve optimal performance and durability.

FAQ

Q:What is 304 stainless steel tubing?

A:304 stainless steel tubing is a type of tubing made from 304 stainless steel, known for its resistance to corrosion, strength, and formability.

Q:What are the common sizes of 304 stainless steel tubing?

A:Common sizes include 1/2″ x 0.065″, 1″ x 0.083″, 2″ x 0.120″, and 4″ x 0.250″. Sizes vary depending on the application.

Q:What types of 304 stainless steel tubing are available?

A:Types include seamless, welded, drawn over mandrel (DOM), and electropolished tubing.

Q:How do I choose the right 304 stainless steel tubing sizes?

A:Consider application requirements, size and dimensions, surface finish, and compliance with industry standards when selecting 304 stainless steel tubing sizes.

Q:How does 304 stainless steel tubing compare with other materials?

A:304 stainless steel tubing offers superior corrosion resistance and strength compared to carbon steel, aluminum, and plastic.

Q:What maintenance is required for 304 stainless steel tubing?

A:Regular cleaning, inspection, and proper storage are essential for maintaining 304 stainless steel tubing sizes.

Q:Can 304 stainless steel tubing be used in high-pressure applications?

A:Yes, 304 stainless steel tubing sizes such as seamless or DOM tubing are suitable for high-pressure applications.