Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100090063158454

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Introduction

The hardness of materials plays a critical role in determining their suitability for various applications. In the realm of stainless steels, 420 stainless steel is notable for its unique balance of hardness, corrosion resistance, and machinability. This article delves into how the hardness of 420 stainless steel impacts its performance, exploring its applications, benefits, limitations, and how it compares to other stainless steel grades. We will also provide insights into how the hardness is achieved and measured, offering a comprehensive understanding of this important material property.

Understanding 420 Stainless Steel

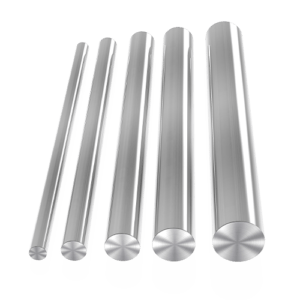

420 stainless steel is a high-carbon, martensitic stainless steel known for its high hardness and good wear resistance. It is commonly used in applications requiring a high degree of hardness and moderate corrosion resistance. Here’s a closer look at the characteristics and composition of 420 stainless steel:

Composition of 420 Stainless Steel

420 stainless steel typically contains the following elements:

- Carbon (C): 0.15-0.40%

- Chromium (Cr): 12.00-14.00%

- Manganese (Mn): 1.00% max

- Silicon (Si): 1.00% max

- Phosphorus (P): 0.040% max

- Sulfur (S): 0.030% max

This composition imparts a combination of hardness, corrosion resistance, and strength, making 420 stainless steel suitable for various demanding applications.

Hardness of 420 Stainless Steel

The hardness of 420 stainless steel is a key factor influencing its performance. Hardness, typically measured using the Rockwell scale (HRc), indicates a material’s resistance to deformation and wear. For 420 stainless steel, the hardness can vary depending on its heat treatment and processing.

Measuring Hardness

The hardness of 420 stainless steel is usually measured using the Rockwell C scale (HRc). The Rockwell test involves applying a specific load to an indenter and measuring the depth of penetration. Higher HRc values indicate greater hardness.

Hardness Range for 420 Stainless Steel

| Condition | Hardness (HRc) |

|---|---|

| As-Rolled | 45-50 HRc |

| Heat Treated (Annealed) | 50-55 HRc |

| Heat Treated (Hardened) | 55-60 HRc |

The hardness of 420 stainless steel can be adjusted through heat treatment processes such as annealing and hardening, which impact its final performance characteristics.

How Hardness Affects Performance

The hardness of 420 stainless steel directly influences its performance in various applications. Here’s a breakdown of how hardness affects different performance aspects:

Wear Resistance

Higher hardness improves the wear resistance of 420 stainless steel, making it suitable for applications where the material is subject to abrasive forces. Tools, knives, and industrial components benefit from the enhanced durability provided by increased hardness.

Machinability

Increased hardness can make 420 stainless steel more challenging to machine. Harder materials require more advanced cutting tools and techniques, potentially increasing manufacturing costs and complexity.

Corrosion Resistance

While 420 stainless steel offers good corrosion resistance due to its chromium content, higher hardness does not significantly impact its corrosion properties. However, the balance between hardness and corrosion resistance should be considered for applications in corrosive environments.

Impact Resistance

Higher hardness generally reduces impact resistance. Although 420 stainless steel can be hardened to achieve high hardness levels, this may come at the expense of its ability to withstand sudden impacts or shock loads.

Applications of 420 Stainless Steel

420 stainless steel is used in various applications where its hardness is advantageous. Here are some common uses:

Cutting Tools

420 stainless steel is often used in the manufacture of cutting tools, such as knives and blades, where high hardness is required for maintaining a sharp edge and durability.

Industrial Components

Components such as valves, pumps, and gears that experience significant wear and require high hardness for effective performance are commonly made from 420 stainless steel.

Medical Instruments

Certain medical instruments that require high hardness for precision and durability are also made from 420 stainless steel, benefiting from its ability to maintain sharpness and resist deformation.

Aerospace and Automotive Parts

In the aerospace and automotive industries, 420 stainless steel is used for various parts and tools that need a combination of hardness and strength to withstand demanding conditions.

Comparing 420 Stainless Steel with Other Grades

To understand the unique properties of 420 stainless steel, it’s useful to compare it with other stainless steel grades, such as 304 and 316. The table below highlights key differences:

| Property | 420 Stainless Steel | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|---|

| Hardness (HRc) | 45-60 HRc | 70-90 HRB | 70-90 HRB |

| Corrosion Resistance | Moderate | High | Very High |

| Tensile Strength | High | Moderate | High |

| Machinability | Moderate | Good | Moderate |

| Typical Applications | Tools, Industrial Components | Kitchen Equipment, Chemical Containers | Marine Equipment, Medical Devices |

Factors Affecting the Hardness of 420 Stainless Steel

The hardness of 420 stainless steel can be influenced by several factors, including:

Heat Treatment

Heat treatment processes, such as annealing and quenching, are used to adjust the hardness of 420 stainless steel. Proper heat treatment can enhance hardness while maintaining other desirable properties.

Carbon Content

The carbon content in 420 stainless steel affects its hardness. Higher carbon levels generally increase hardness but may impact other properties such as ductility.

Alloying Elements

The presence of alloying elements like chromium impacts the hardness and overall performance of 420 stainless steel. Adjustments to the composition can tailor the material for specific applications.

Conclusion

The hardness of 420 stainless steel plays a pivotal role in its performance and suitability for various applications. Its ability to achieve high hardness levels provides significant benefits in terms of wear resistance and durability, making it a valuable material for cutting tools, industrial components, and more. However, the trade-offs in machinability and impact resistance must be considered when selecting 420 stainless steel for specific uses. By understanding the relationship between hardness and performance, manufacturers and engineers can make informed decisions to optimize the use of this versatile material.

FAQ

Q:What is the typical hardness range for 420 stainless steel?

A:The typical hardness range for 420 stainless steel is between 45-60 HRc, depending on the heat treatment and processing conditions.

Q:How does the hardness of 420 stainless steel compare to 304 and 316 stainless steels?

A:420 stainless steel generally has higher hardness compared to 304 and 316 stainless steels, which have lower hardness but higher corrosion resistance.

Q:Can the hardness of 420 stainless steel be adjusted?

A:Yes, the hardness of 420 stainless steel can be adjusted through heat treatment processes such as annealing and hardening.

Q:What are the main applications of 420 stainless steel?

A:420 stainless steel is commonly used in cutting tools, industrial components, medical instruments, and certain aerospace and automotive parts.

Q:Does higher hardness affect the corrosion resistance of 420 stainless steel?

A:Higher hardness does not significantly impact the corrosion resistance of 420 stainless steel, which is primarily determined by its chromium content.