Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100090063158454

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Introduction

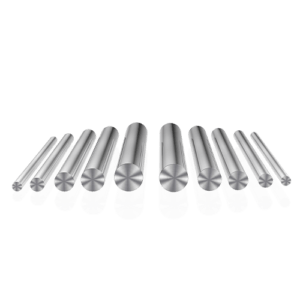

In the realm of industrial applications, selecting the right materials is crucial for ensuring performance, durability, and safety. Among the various options available, Qilu 316 stainless steel tubing stands out as a superior choice for many industries. This high-quality tubing is renowned for its exceptional corrosion resistance, mechanical strength, and versatility. In this comprehensive guide, we will explore why Qilu 316 stainless steel tubing is the best choice for your industrial needs, examining its properties, benefits, and applications.

Understanding Qilu 316 Stainless Steel Tubing

What Is Qilu 316 Stainless Steel Tubing?

Qilu 316 stainless steel tubing is made from a specific grade of stainless steel known as 316. This alloy is composed of iron, chromium, nickel, and molybdenum. The addition of molybdenum enhances its resistance to corrosion, particularly in chloride environments, making it ideal for a wide range of industrial applications.

Composition and Characteristics

The key characteristics of Qilu 316 stainless steel tubing include:

- Corrosion Resistance: Superior to many other stainless steel grades, especially in marine and chloride environments.

- Strength and Durability: High tensile strength and resistance to wear and tear.

- Temperature Tolerance: Effective in both high and low-temperature environments.

- Hygienic Properties: Non-porous and easy to clean, making it suitable for sanitary applications.

Benefits of Using Qilu 316 Stainless Steel Tubing

Superior Corrosion Resistance

One of the primary benefits of Qilu 316 stainless steel tube is its exceptional corrosion resistance. The presence of molybdenum in the alloy provides enhanced protection against rust and corrosion, particularly in environments with high chloride concentrations, such as seawater or industrial chemicals. This property ensures longevity and reliability in harsh conditions.

High Mechanical Strength

Qilu 316 stainless steel tubing is known for its high mechanical strength. It can withstand significant pressure and mechanical stress without deforming or failing. This strength is critical in applications where structural integrity is essential, such as in aerospace, automotive, and construction industries.

Versatility in Applications

The versatility of Qilu 316 stainless steel tube makes it suitable for a wide range of applications. From chemical processing and pharmaceutical manufacturing to food and beverage industries, its adaptability to different environments and requirements is a significant advantage. Its ability to maintain performance under various conditions makes it a preferred choice across multiple sectors.

Excellent Temperature Resistance

This tubing performs well across a broad temperature range. It maintains its properties and structural integrity in both high-temperature and cryogenic environments. This characteristic is essential for industries that deal with extreme temperatures, such as petrochemical and aerospace sectors.

Comparing Qilu 316 Stainless Steel Tubing with Other Materials

Comparison Table: Qilu 316 vs. Other Stainless Steel Grades

| Feature | Qilu 316 Stainless Steel | Qilu 304 Stainless Steel | Carbon Steel | Aluminum |

|---|---|---|---|---|

| Corrosion Resistance | Excellent | Good | Poor | Good |

| Strength | High | Medium | High | Low |

| Temperature Tolerance | High | Medium | Medium | Low |

| Hygiene | Excellent | Good | Poor | Good |

| Cost | High | Medium | Low | Medium |

This comparison highlights the advantages of Qilu 316 stainless steel tube over other common materials, emphasizing its superior corrosion resistance, strength, and temperature tolerance.

Applications of Qilu 316 Stainless Steel Tubing

Chemical Processing

In chemical processing industries, Qilu 316 stainless steel tubing is used for transporting corrosive chemicals and fluids. Its ability to resist chemical attack ensures safety and longevity in these demanding applications.

Pharmaceutical and Food Industries

The hygienic properties of Qilu 316 stainless steel tube make it ideal for use in pharmaceutical and food processing industries. It meets stringent cleanliness standards and resists contamination, ensuring product purity and safety.

Aerospace and Automotive Industries

In aerospace and automotive industries, the high mechanical strength and temperature tolerance of Qilu 316 stainless steel tubing are crucial. It is used in various components and systems where durability and performance are critical.

Marine Applications

Due to its exceptional corrosion resistance, Qilu 316 stainless steel tube is widely used in marine applications. It withstands the harsh marine environment, making it suitable for use in ships, offshore structures, and other marine equipment.

Maintenance and Care for Qilu 316 Stainless Steel Tubing

Cleaning and Sanitation

To maintain the performance and appearance of Qilu 316 stainless steel tubing, regular cleaning is essential. Use non-abrasive cleaners and avoid harsh chemicals that could damage the surface. For sanitary applications, ensure that the tubing is thoroughly cleaned and sanitized to prevent contamination.

Inspection and Monitoring

Regular inspection and monitoring of Qilu 316 stainless steel tube are necessary to detect any signs of wear, corrosion, or damage. Routine checks help ensure that the tubing remains in optimal condition and performs effectively.

Longevity and Replacement

Qilu 316 stainless steel tubing is known for its longevity, but periodic replacement may be required depending on the application and environmental conditions. Assess the tubing regularly and replace it when necessary to maintain operational efficiency and safety.

Conclusion

Qilu 316 stainless steel tubing is an exceptional choice for industrial applications due to its superior corrosion resistance, high mechanical strength, versatility, and temperature tolerance. Its benefits make it suitable for a wide range of industries, including chemical processing, pharmaceuticals, aerospace, and marine applications. By understanding its advantages and applications, you can make an informed decision about using Qilu 316 stainless steel tube for your specific needs.

FAQ

What makes Qilu 316 stainless steel tubing different from other stainless steel grades?

Qilu 316 stainless steel tubing differs from other grades due to its higher corrosion resistance, particularly against chlorides, thanks to the addition of molybdenum. It also offers superior mechanical strength and temperature tolerance.

How does Qilu 316 stainless steel tube perform in high-temperature environments?

Qilu 316 stainless steel tube performs well in high-temperature environments. It maintains its strength and structural integrity even at elevated temperatures, making it suitable for applications in industries that deal with extreme heat.

Is Qilu 316 stainless steel tubing suitable for food and beverage applications?

Yes, Qilu 316 stainless steel tubing is suitable for food and beverage applications due to its hygienic properties. It resists contamination and is easy to clean, ensuring the safety and purity of food and beverage products.

What is the typical lifespan of Qilu 316 stainless steel tubing?

The typical lifespan of Qilu 316 stainless steel tubing depends on the application and environmental conditions. Generally, it is known for its longevity and can last many years with proper maintenance and care.

How should I clean Qilu 316 stainless steel tubing?

To clean Qilu 316 stainless steel tubing, use non-abrasive cleaners and avoid harsh chemicals that could damage the surface. For sanitary applications, ensure thorough cleaning and sanitization to prevent contamination.