Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100090063158454

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Introduction

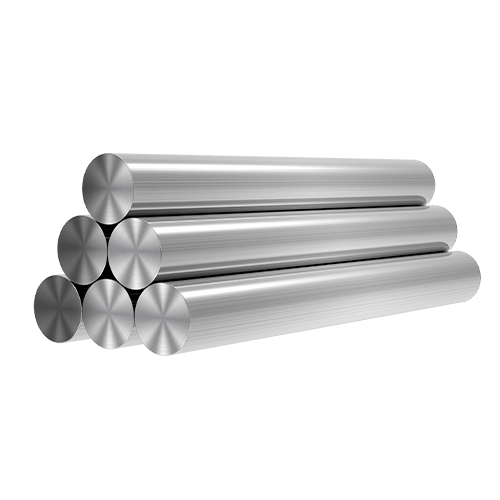

410 stainless steel is a martensitic stainless steel that is widely recognized for its high strength, moderate corrosion resistance, and excellent performance at elevated temperatures. It is a popular choice for components exposed to harsh conditions due to its unique blend of properties. This blog will explore why 410 stainless steel round bar is especially suited for high-temperature environments and what makes it a material of choice in various industrial applications.

Understanding 410 Stainless Steel

410 stainless steel is part of the martensitic group of stainless steels. It is characterized by its high chromium content, typically around 11.5%, which contributes to its strength and hardness. The martensitic structure provides excellent toughness and wear resistance, making it suitable for various demanding applications.

Key Properties of 410 Stainless Steel

- Chromium Content: Approximately 11.5%

- Carbon Content: Up to 0.15%

- Density: 7.75 g/cm³

- Tensile Strength: Up to 750 MPa (108,000 psi)

- Hardness: Typically 50-55 HRC

These properties make 410 stainless steel round bar an excellent choice for high-temperature environments where durability and resistance to wear are crucial.

Advantages of 410 Stainless Steel Round Bar

410 stainless steel round bar offers several advantages for high-temperature applications:

- High Strength and Hardness: The martensitic structure of 410 stainless steel provides superior strength and hardness, which are critical for components subjected to mechanical stress and high temperatures.

- Wear and Tear Resistance: Its hardness contributes to excellent wear resistance, making it suitable for applications where parts are subject to abrasion or erosion.

- Moderate Corrosion Resistance: While not as corrosion-resistant as austenitic stainless steels, 410 stainless steel offers reasonable resistance to oxidation and corrosion, especially in high-temperature environments.

Applications in High-Temperature Environments

410 stainless steel round bar is used in various high-temperature applications due to its unique properties. Common uses include:

- Aerospace Components: Parts such as turbine blades and engine components that require high strength and durability.

- Automotive Industry: Exhaust systems, valve seats, and other high-stress components.

- Oil and Gas Industry: Components like valve bodies and pump shafts exposed to extreme conditions.

- Industrial Machinery: Wear parts and cutting tools that endure significant wear and high operational temperatures.

Properties of 410 Stainless Steel Round Bar in High-Temperature Conditions

The performance of 410 stainless steel round bar under high-temperature conditions is influenced by several factors. These include:

- Thermal Expansion: 410 stainless steel has a coefficient of thermal expansion that affects how it responds to temperature changes.

- Creep Resistance: At elevated temperatures, materials can deform under stress over time. 410 stainless steel exhibits reasonable creep resistance, maintaining its shape and strength under long-term stress.

- Oxidation Resistance: Though it offers moderate resistance, 410 stainless steel can oxidize over prolonged exposure to high temperatures. However, it still performs well in environments where oxidation is manageable.

Table: Thermal and Mechanical Properties of 410 Stainless Steel Round Bar

| Property | Value |

|---|---|

| Coefficient of Thermal Expansion (20-100°C) | 11.7 × 10^-6 /°C |

| Creep Strength (MPa at 650°C) | 50-70 |

| Oxidation Resistance | Moderate |

| Melting Point | Approximately 1425°C (2597°F) |

| Maximum Service Temperature | 600°C (1112°F) |

Comparison with Other Stainless Steels

While 410 stainless steel round bar offers numerous benefits, it is essential to compare it with other stainless steel grades to understand its relative advantages:

- Versus 304 Stainless Steel: 304 stainless steel offers better corrosion resistance but is less hard and wear-resistant compared to 410.

- Versus 316 Stainless Steel: 316 stainless steel provides superior corrosion resistance, especially against chlorides, but at the cost of lower hardness.

Understanding these differences helps in selecting the right material for specific high-temperature applications.

Conclusion

410 stainless steel round bar is a robust material well-suited for high-temperature environments due to its high strength, wear resistance, and moderate corrosion resistance. Its properties make it an excellent choice for various applications, from aerospace to industrial machinery. While it may not offer the same level of corrosion resistance as some other stainless steels, its hardness and strength at elevated temperatures make it a valuable material in many demanding industries.

FAQ

Q: What are the main applications of 410 stainless steel round bar?

A: 410 stainless steel round bar is used in aerospace components, automotive parts, oil and gas equipment, and industrial machinery due to its strength and wear resistance.

Q: How does 410 stainless steel perform under high temperatures?

A: 410 stainless steel performs well under high temperatures, offering good strength and hardness, though it has moderate oxidation resistance and can be prone to creep over extended periods.

Q: Can 410 stainless steel round bar be used in highly corrosive environments?

A: While 410 stainless steel has some corrosion resistance, it is not the best choice for highly corrosive environments. For better corrosion resistance, grades like 316 stainless steel are recommended.

Q: What are the main factors affecting the performance of 410 stainless steel in high-temperature conditions?

A: Key factors include thermal expansion, creep resistance, and oxidation resistance. Understanding these factors helps in optimizing the material for specific applications.

Q: How does 410 stainless steel compare to other stainless steel grades in terms of hardness?

A: 410 stainless steel is generally harder than grades like 304 and 316 stainless steel, making it more suitable for applications requiring high wear resistance.