Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100090063158454

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Introduction

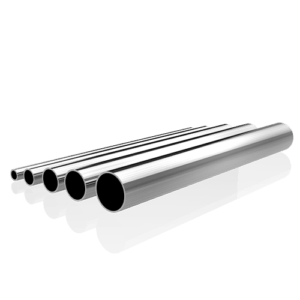

304 stainless steel tubing is a popular choice in the construction industry due to its exceptional properties and versatility. Known for its durability, resistance to corrosion, and aesthetic appeal, this material offers numerous benefits for a wide range of applications. In this blog, we will explore the advantages of using 304 stainless steel tubing in construction, its key features, and why it is an excellent choice for various structural and design needs.

Key Features of 304 Stainless Steel Tubing

304 stainless steel tubing stands out in the construction industry due to its unique properties. Understanding these features can help in appreciating why it is a preferred material for many applications:

Corrosion Resistance

304 stainless steel is highly resistant to rust and corrosion, making it suitable for use in harsh environments. Its chromium content helps form a passive layer of chromium oxide on the surface, which protects it from various corrosive agents.

Strength and Durability

The material boasts excellent tensile strength and durability. 304 stainless steel can withstand substantial stress and pressure, making it ideal for structural applications where strength is crucial.

Aesthetic Appeal

The sleek, polished finish of 304 stainless steel tubing adds an attractive aesthetic to construction projects. Its shiny appearance is often chosen for architectural elements and decorative purposes.

Temperature Tolerance

304 stainless steel tubing performs well in a wide range of temperatures. It can maintain its properties in both high and low temperatures, making it suitable for diverse environmental conditions.

Ease of Maintenance

The smooth surface of 304 stainless steel tubing is easy to clean and maintain. It does not require extensive upkeep, which reduces long-term maintenance costs and ensures a clean, professional appearance.

Applications of 304 Stainless Steel Tubing in Construction

The versatility of 304 stainless steel tubing makes it suitable for various construction applications. Here are some common uses:

Structural Supports

304 stainless steel tubing is used for structural supports due to its strength and durability. It is often employed in frames, columns, and beams to provide stability and load-bearing capacity.

Handrails and Balustrades

The aesthetic appeal and corrosion resistance of 304 stainless steel tubing make it a popular choice for handrails and balustrades. It provides both safety and a modern look for staircases, balconies, and walkways.

Architectural Elements

In architectural design, 304 stainless steel is used for decorative elements such as curtain rods, railings, and exterior cladding. Its polished finish enhances the visual appeal of buildings and structures.

Plumbing and HVAC Systems

304 stainless steel tubing is also utilized in plumbing and HVAC systems due to its resistance to corrosion and ability to handle various temperatures. It is used for piping, conduit systems, and ductwork.

Outdoor Installations

For outdoor installations, such as in gardens or public spaces, 304 stainless steel provides durability and resistance to environmental factors. It is ideal for creating structures that need to withstand weather conditions.

Benefits of Using 304 Stainless Steel Tubing

The benefits of using 304 stainless steel tubing in construction are extensive. Here’s a closer look at why it is a preferred material:

Superior Corrosion Resistance

One of the primary advantages of 304 stainless steel is its superior resistance to corrosion. This property ensures that the tubing remains functional and visually appealing over time, even in challenging environments.

Long-Term Cost Savings

While the initial cost of 304 stainless steel may be higher than other materials, its durability and low maintenance requirements lead to long-term cost savings. Its longevity reduces the need for frequent replacements and repairs.

Versatility

304 stainless steel tubing’s versatility makes it suitable for a wide range of applications. Its ability to be easily fabricated and customized allows it to meet specific design and structural requirements.

Environmental Benefits

Stainless steel is 100% recyclable, making it an environmentally friendly choice. Using 304 stainless steel in construction supports sustainable building practices and reduces environmental impact.

Comparison of 304 Stainless Steel Tubing with Other Materials

The following table highlights some key comparisons between 304 stainless steel and other common materials used in construction:

| Material | Corrosion Resistance | Strength | Maintenance | Aesthetic Appeal |

|---|---|---|---|---|

| 304 Stainless Steel | Excellent | High | Low | High |

| Carbon Steel | Moderate | High | Moderate | Low |

| Aluminum | Good | Moderate | Low | Moderate |

| Plastic | Varies | Low | Low | Low |

Choosing the Right 304 Stainless Steel Tubing

When selecting 304 stainless steel tubing for construction projects, consider the following factors:

Project Requirements

Assess the specific requirements of your project, including strength, corrosion resistance, and aesthetic needs. Choose tubing that meets these criteria to ensure optimal performance.

Size and Specifications

Select the appropriate size and specifications of 304 stainless steel based on your project’s structural and design needs. Consider factors such as diameter, wall thickness, and length.

Fabrication and Installation

Ensure that the tubing can be easily fabricated and installed according to your project’s requirements. Consult with professionals to confirm that the tubing will be properly integrated into your construction plans.

Budget and Cost

Evaluate your budget and compare the costs of 304 stainless steel tubing with other materials. While it may be more expensive initially, consider the long-term savings due to its durability and low maintenance.

Conclusion

304 stainless steel tubing offers numerous benefits for construction projects, including superior corrosion resistance, strength, and aesthetic appeal. Its versatility makes it suitable for a wide range of applications, from structural supports to decorative elements. By understanding its advantages and selecting the right specifications, you can ensure that 304 stainless steel enhances the durability and appearance of your construction projects.

FAQ

What makes 304 stainless steel tubing a good choice for construction?

304 stainless steel tubing is highly resistant to corrosion, strong, and durable. Its aesthetic appeal and ease of maintenance also make it a preferred material for various construction applications.

How does 304 stainless steel compare to other materials?

Compared to carbon steel, aluminum, and plastic, 304 stainless steel offers superior corrosion resistance, high strength, and a more polished appearance. It also requires less maintenance and is more durable.

Can 304 stainless steel tubing be used outdoors?

Yes, 304 stainless steel tubing is suitable for outdoor use due to its excellent corrosion resistance. It can withstand environmental factors such as moisture and UV exposure, making it ideal for outdoor installations.

What factors should I consider when choosing 304 stainless steel?

Consider the project’s requirements, including strength, corrosion resistance, and aesthetic needs. Also, evaluate the size, specifications, and cost of the tubing to ensure it meets your project’s needs.

Is 304 stainless steel tubing environmentally friendly?

Yes, 304 stainless steel tubing is environmentally friendly because it is 100% recyclable. Using stainless steel supports sustainable building practices and reduces environmental impact.