Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100090063158454

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Introduction

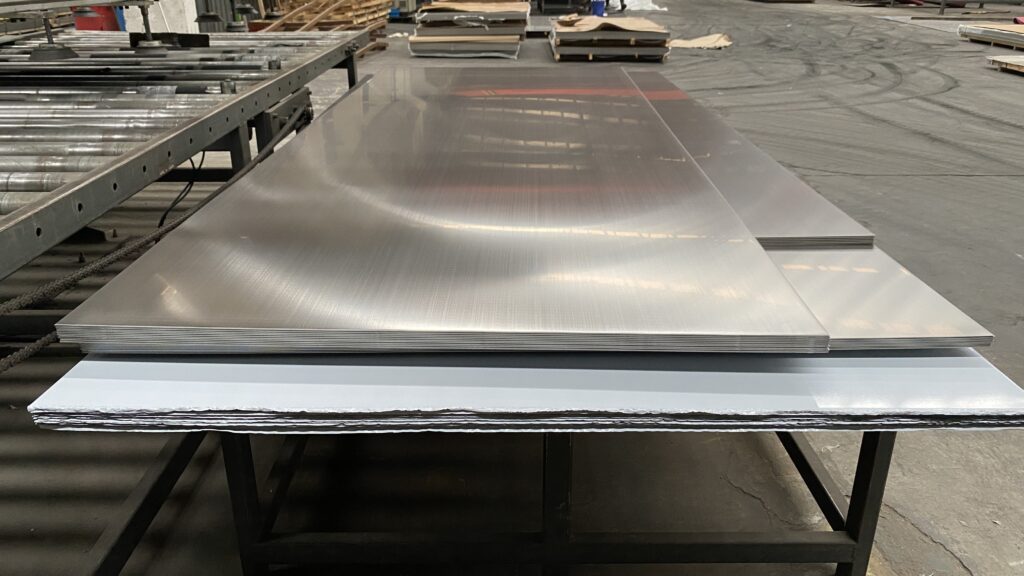

Choosing the right material for your project is crucial, and 330 stainless steel is an excellent option for various applications. Known for its unique properties, it provides exceptional strength and corrosion resistance. In this blog, we will delve into the characteristics of 330 stainless steel, its applications, and tips on how to select the right grade for your needs.

What is 330 Stainless Steel?

330 stainless steel is an austenitic alloy primarily composed of iron, nickel, and chromium. This combination gives it remarkable heat resistance and oxidation resistance at elevated temperatures. Its composition typically includes 34% nickel and 18% chromium, making it ideal for applications in harsh environments.

Key Properties of 330 Stainless Steel

330 stainless steel boasts several significant properties that make it a preferred choice in various industries:

- High-Temperature Resistance: Retains strength at elevated temperatures, suitable for applications up to 2200°F (1200°C).

- Corrosion Resistance: Excellent resistance to oxidation, making it ideal for high-temperature applications.

- Workability: Good formability and weldability, allowing for versatile use in different projects.

Key Properties of 330 Stainless Steel

| Property | Value |

|---|---|

| Composition (Ni) | 34% |

| Composition (Cr) | 18% |

| Density | 7.93 g/cm³ |

| Melting Point | 1400-1450°C |

| Ultimate Tensile Strength | 620 MPa |

Applications of 330 Stainless Steel

The versatility of 330 stainless steel makes it suitable for numerous applications:

- Industrial Furnaces: Used in components like heating elements and combustion chambers.

- Heat Exchangers: Ideal for applications requiring high heat transfer efficiency.

- Chemical Processing: Commonly used in reactors and pipelines due to its corrosion resistance.

- Aerospace: Suitable for parts exposed to extreme conditions.

Factors to Consider When Choosing 330 Stainless Steel

When selecting 330 stainless steel for your project, consider the following factors:

Temperature Resistance

Evaluate the operating temperature of your application. 330 stainless steel is optimal for high-temperature environments, ensuring longevity and performance.

Corrosion Resistance Needs

Determine the corrosive nature of the environment. 330 stainless steel excels in oxidizing atmospheres, making it a go-to choice for chemical processing.

Mechanical Properties

Assess the mechanical requirements, such as tensile strength and ductility. Ensure that the selected grade meets the specifications for your project.

Fabrication Requirements

Consider how the stainless steel will be fabricated. 330 stainless steel can be welded and formed, but specific techniques may be required to ensure integrity.

Common Misconceptions About 330 Stainless Steel

Despite its popularity, there are several misconceptions regarding 330 stainless steel:

- It’s Only for High-Temperature Use: While it excels in high temperatures, it is also suitable for moderate environments.

- It’s Expensive: The initial cost might be higher, but its durability leads to lower long-term expenses.

Conclusion

Selecting stainless steel 330 for your project can offer significant advantages, from high-temperature performance to corrosion resistance. By considering factors such as temperature, corrosion needs, and fabrication, you can make an informed choice that meets your project requirements.

FAQ

What industries commonly use 330 stainless steel?

stainless steel 330 is widely used in industries such as aerospace, chemical processing, and industrial manufacturing.

Can 330 stainless steel be welded?

Yes, 330 stainless steel can be welded using appropriate techniques, though pre-heating may be necessary.

How does 330 stainless steel compare to other alloys?

stainless steel 330 offers superior high-temperature resistance compared to many other stainless steel grades, making it ideal for specific applications.

Is 330 stainless steel prone to rust?

While it is highly resistant to oxidation, exposure to certain chemicals may lead to corrosion over time.

What is the best way to maintain 330 stainless steel?

Regular cleaning with appropriate agents can help maintain its appearance and performance over time.

By understanding these aspects, you can effectively choose 330 stainless steel for your specific needs, ensuring the ultimate success of your project.