Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100090063158454

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Introduction

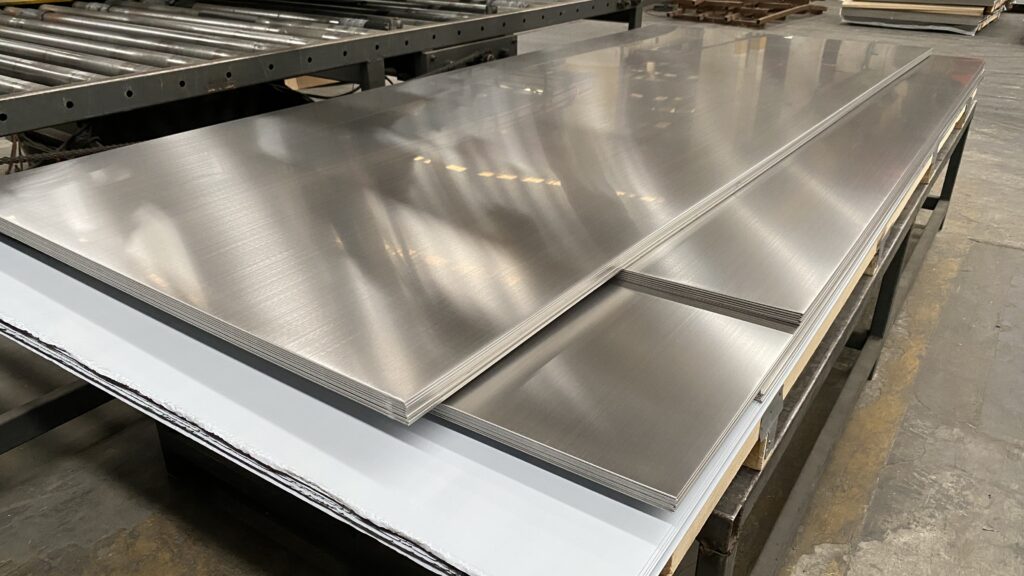

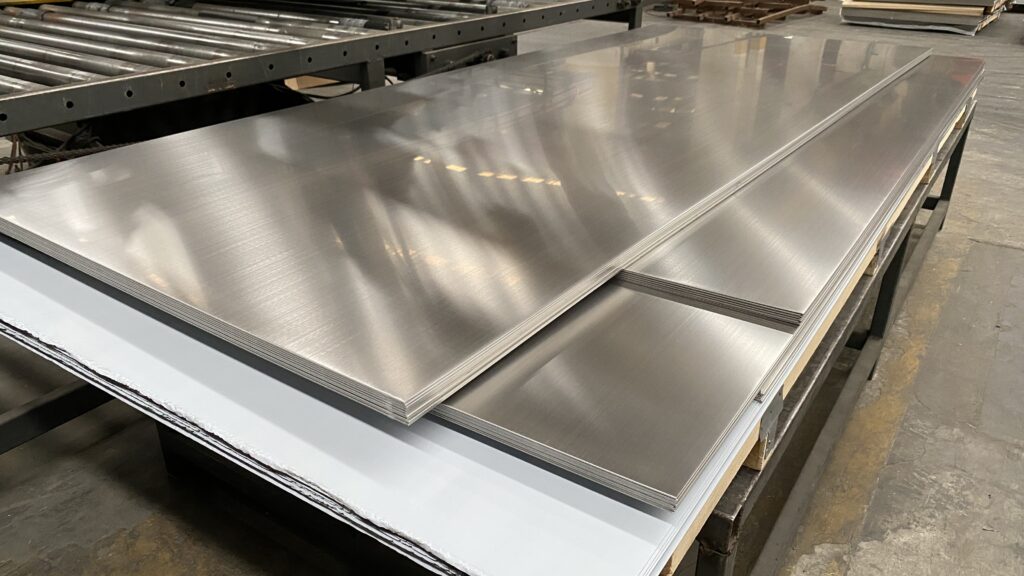

304 stainless steel is among the most widely used stainless steel grades worldwide, valued for its durability, resistance to corrosion, and aesthetic appeal. However, there’s often confusion about whether or not it is magnetic. For engineers, manufacturers, and consumers, understanding the magnetic properties of 304 stainless steel is crucial to selecting the right material for various applications, especially those where magnetism can interfere with performance. In this blog, we’ll explore why 304 stainless steel may exhibit magnetic properties, when it is likely to do so, and how these properties impact its usability. Let’s dive into the science, factors, and practical insights around 304 stainless steel magnetic properties.

What is 304 Stainless Steel?

304 stainless steel is an austenitic stainless steel alloy, containing approximately 18-20% chromium and 8-10.5% nickel, along with small amounts of carbon, manganese, and silicon. These elements contribute to its impressive strength, rust resistance, and formability, making it an excellent choice for various applications, from kitchen appliances to chemical processing equipment. However, its austenitic structure is typically non-magnetic, setting it apart from other stainless steel types like ferritic or martensitic steels. Yet, certain processing methods can induce magnetic properties in 304 stainless steel, causing it to exhibit some level of magnetism.

| Composition of 304 Stainless Steel | Percentage (%) |

|---|---|

| Chromium | 18-20 |

| Nickel | 8-10.5 |

| Manganese | ≤ 2.0 |

| Silicon | ≤ 1.0 |

| Carbon | ≤ 0.08 |

| Phosphorus | ≤ 0.045 |

| Sulfur | ≤ 0.03 |

| Iron | Balance |

The Science Behind 304 Stainless Steel Magnetic Properties

1. Austenitic Structure and Non-Magnetic Nature

The primary reason that 304 stainless steel is generally non-magnetic lies in its austenitic crystal structure. Austenite, stabilized by the high nickel and chromium content, does not align with magnetic fields, resulting in a non-magnetic material in its annealed or unprocessed state.

2. Transformation to Martensitic Structure

304 stainless steel can exhibit magnetic properties when subjected to mechanical deformation, such as cold working. Cold working, or plastic deformation, involves manipulating the metal at low temperatures, which transforms part of its structure from austenite to martensite—a magnetic phase. This transformation is known as the “strain-induced martensitic transformation,” and it is responsible for any magnetic response in 304 stainless steel.

3. Effect of Temperature on Magnetism

Temperature also plays a role in the magnetic properties of 304 stainless steel. High temperatures can restore the non-magnetic austenitic phase, while exposure to extreme cold can induce further martensitic transformation, making the steel more magnetic. Thus, heat treatment can help in reducing any magnetic properties gained during cold working.

Factors Influencing Magnetism in 304 Stainless Steel

| Factor | Effect on Magnetic Properties | Explanation |

|---|---|---|

| Cold Working | Increases magnetism | Strain-induced transformation to martensitic structure |

| Heat Treatment | Reduces magnetism | Restores austenitic structure, reduces martensitic content |

| Welding | May slightly increase magnetism in heat-affected zones | Localized stress and transformation in welded areas |

| Temperature Changes | Cold temperatures increase, high temperatures decrease magnetism | Extreme cold promotes martensitic transformation |

| Thickness of Material | Thicker sections may retain more austenitic structure, less magnetism | Reduced effect of strain in thicker areas |

Applications of 304 Stainless Steel and Magnetic Considerations

Even with occasional magnetism, 304 stainless steel remains the go-to choice for many industries. However, it’s essential to understand where magnetic properties could impact the performance or suitability of the material.

Medical Equipment

Due to its non-reactive properties and corrosion resistance, 304 stainless steel is widely used in medical devices and surgical tools. In these applications, magnetic properties must be carefully controlled, as they may interfere with MRI machines and other sensitive equipment.

Food and Beverage Industry

304 stainless steel is often chosen for food-grade applications due to its sanitary properties. While magnetism is not typically a concern in these applications, 304 stainless steel’s low magnetic response after forming makes it ideal for food storage and preparation.

Electronics and Communications

In electronic devices and communication infrastructure, non-magnetic materials are often necessary to avoid interference with electronic signals. 304 stainless steel’s low magnetic properties after annealing make it suitable for casings and components where electromagnetic interference (EMI) could be an issue.

How to Test the Magnetic Properties of 304 Stainless Steel

If you need to determine whether a piece of 304 stainless steel has magnetic properties, here are some simple testing methods:

- Use a Small Magnet: Attach a small magnet to the stainless steel. If it sticks, there’s a martensitic transformation present, likely due to cold working.

- Visual Inspection for Cold Worked Areas: Look for visible signs of cold working, such as bending or machining marks, which can indicate areas with increased magnetic response.

- Eddy Current Testing: This is a non-destructive testing method used to detect changes in conductivity and can indirectly reveal any martensitic regions.

Benefits of Using Non-Magnetic 304 Stainless Steel in Industry

1. Interference-Free Environment

Non-magnetic 304 stainless steel is ideal for environments where magnetic interference could affect precision, such as in medical, aerospace, and scientific equipment.

2. Enhanced Corrosion Resistance

The non-magnetic austenitic structure is also associated with high corrosion resistance, making 304 stainless steel highly durable in acidic and marine environments.

3. Versatile and Easy to Fabricate

Even with minimal magnetic response after cold working, 304 stainless steel is still easy to cut, weld, and form, allowing for versatile design and application without losing its core characteristics.

Table: Comparison of 304 Stainless Steel Magnetic Response in Different Conditions

| Condition | Magnetic Response | Explanation |

|---|---|---|

| Annealed | Non-magnetic | Austenitic structure remains intact |

| Cold Worked | Magnetic | Strain-induced martensitic transformation |

| Heat Treated | Reduced Magnetism | Restores austenitic phase, reducing magnetic properties |

| Welded | Slightly Magnetic | Localized martensitic transformation in heat-affected zones |

| Cryogenic Temperatures | Increased Magnetism | Extreme cold enhances martensitic transformation |

FAQ on 304 Stainless Steel Magnetic Properties

Q1: Why does cold working make 304 stainless steel magnetic?

A1: Cold working transforms part of the austenitic structure into a martensitic structure, which is magnetic.

Q2: Can heat treatment make 304 stainless steel completely non-magnetic?

A2: Heat treatment can reduce magnetic properties by restoring the austenitic structure, though it may not eliminate magnetism completely if heavy cold working occurred.

Q3: Is 304 stainless steel the only non-magnetic stainless steel?

A3: No, other austenitic grades like 316 stainless steel are also non-magnetic, although they may show slight magnetism after cold working.

Q4: Does the magnetic property affect the durability of 304 stainless steel?

A4: Magnetic properties do not affect its corrosion resistance or durability; these properties are determined by its chemical composition.

Q5: Are there applications where the magnetic properties of 304 stainless steel are advantageous?

A5: Yes, applications like magnetic door catches or temporary fastenings can utilize cold-worked 304 stainless steel where slight magnetism is useful.

Conclusion

304 stainless steel, while typically non-magnetic, can exhibit magnetic properties under certain conditions like cold working or exposure to low temperatures. Understanding these magnetic properties is essential for applications where magnetism can affect performance, especially in fields like electronics, medical equipment, and food processing. By comprehensively understanding 304 stainless steel’s magnetic behavior, industries can better harness its benefits and make informed material choices based on specific application needs.

With this knowledge, engineers and designers can select and process 304 stainless steel to either minimize or exploit its magnetic properties, ensuring the best performance for their applications.