Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100090063158454

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

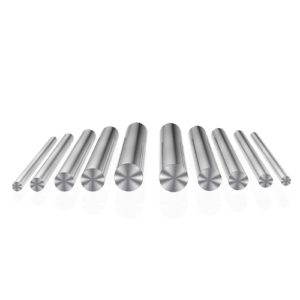

Stainless steel 303 is a versatile alloy within the 300 series of austenitic stainless steels, renowned for its exceptional machinability. This unique property makes it a preferred choice in various manufacturing applications, from automotive and aerospace to medical and general engineering. In this comprehensive guide, we will delve deep into the characteristics, properties, and applications of stainless steel 303, providing you with the knowledge needed to make informed decisions for your projects.

Understanding Stainless Steel 303

Stainless steel 303 is an alloy primarily composed of iron, chromium, and nickel, with the strategic addition of sulfur and phosphorus to significantly enhance its machinability. These elements play a crucial role in the alloy’s performance. Chromium, a key component of stainless steels, forms a protective oxide layer on the surface, providing excellent resistance to corrosion. Nickel contributes to the alloy’s strength, ductility, and toughness.

The addition of sulfur and phosphorus, however, is what truly sets stainless steel 303 apart. These elements form sulfide and phosphide inclusions, which act as lubricants during machining operations. These inclusions reduce friction between the cutting tool and the workpiece, leading to smoother cuts, reduced tool wear, and improved surface finish.

Properties of Stainless Steel 303

- Machinability: As mentioned, the most defining characteristic of stainless steel 303 is its exceptional machinability. The presence of sulfur and phosphorus significantly reduces the cutting forces required during machining, making it easier to cut, drill, and turn compared to other stainless steels. This results in increased productivity, reduced machining time, and lower costs.

- Corrosion Resistance: While not as corrosion-resistant as some other stainless steels, such as 316L, 303 still offers good resistance to oxidation and corrosion in many environments. It is commonly used in applications where exposure to atmospheric conditions or mild chemicals is expected. However, it is important to note that 303 may not be suitable for highly corrosive environments or applications involving exposure to chloride-rich solutions.

- Strength and Ductility: Stainless steel 303 possesses a good balance of strength and ductility. It exhibits high tensile strength, which allows it to withstand significant loads without yielding. Additionally, its ductility enables it to undergo plastic deformation without fracturing, making it suitable for various forming and bending operations.

- Heat Resistance: 303 stainless steel exhibits moderate heat resistance, making it suitable for applications involving elevated temperatures. However, its heat resistance is lower compared to some other stainless steel grades, such as 304. It is important to consider the specific temperature requirements of the application and consult with a materials engineer to ensure that 303 is the appropriate choice.

Applications of Stainless Steel 303

Due to its excellent machinability and combination of properties, stainless steel 303 finds widespread applications in various industries, including:

- Automotive: In the automotive industry, 303 stainless steel is used to manufacture a variety of components, including fasteners, bushings, valve stems, and other small machined parts. Its machinability allows for precise and efficient production of these components, ensuring optimal performance and durability.

- Aerospace: In the aerospace industry, where weight reduction and high performance are critical, 303 stainless steel is used to manufacture small precision parts and components. Its machinability enables the production of complex shapes and intricate details, while its corrosion resistance and strength ensure the reliability of these components in harsh environments.

- Medical: In the medical industry, 303 stainless steel is used to manufacture surgical instruments, implants, and other medical devices. Its biocompatibility, corrosion resistance, and machinability make it a suitable choice for these applications. Additionally, its ability to be sterilized and cleaned without compromising its properties is essential in medical settings.

- General Engineering: In general engineering applications, 303 stainless steel is used to fabricate various mechanical components, such as gears, shafts, bearings, and pump impellers. Its machinability allows for the production of these components with precise tolerances and smooth finishes, ensuring optimal performance and efficiency.

Chemical Composition and Physical Properties

| Property | Value |

|---|---|

| Carbon, % | 0.15 max |

| Manganese, % | 2.00 max |

| Phosphorus, % | 0.15 max |

| Sulfur, % | 0.15 max |

| Silicon, % | 1.00 max |

| Chromium, % | 17.00-19.00 |

| Nickel, % | 8.00-10.00 |

| Density, g/cm³ | 7.93 |

| Melting Point, °C | 1400-1450 |

| Tensile Strength, MPa | 515-690 |

| Yield Strength, MPa | 275-380 |

| Elongation, % | 40-50 |

The Machining Process for Stainless Steel 303

The superior machinability of stainless steel 303 can be attributed to the presence of sulfur and phosphorus, which act as effective lubricants during machining. These elements reduce friction between the cutting tool and the workpiece, leading to smoother cuts, reduced tool wear, and improved surface finish. Common machining processes for 303 stainless steel include:

- Turning: Turning involves removing material from a rotating workpiece using a cutting tool to create cylindrical shapes. The excellent machinability of 303 stainless steel allows for precise and efficient turning operations, resulting in high-quality components with minimal surface defects.

- Milling: Milling involves removing material from a workpiece using a rotating cutter with multiple cutting edges. 303 stainless steel’s machinability enables the production of complex shapes and intricate details through milling operations.

- Drilling: Drilling involves creating holes in a workpiece using a rotating drill bit. The reduced cutting forces and improved chip evacuation associated with 303 stainless steel make drilling operations more efficient and accurate.

- Tapping: Tapping involves creating internal threads in a drilled hole using a cutting tool called a tap. The machinability of 303 stainless steel facilitates the production of clean and accurate threads, ensuring proper fit and function of threaded components.

Advantages of Using Stainless Steel 303

- Excellent Machinability: The primary advantage of stainless steel 303 is its exceptional machinability. This property significantly reduces machining time, lowers production costs, and enables the production of complex shapes and intricate details.

- Corrosion Resistance: 303 stainless steel offers good resistance to corrosion in many environments, including atmospheric conditions and exposure to mild chemicals. This makes it suitable for a wide range of applications where corrosion resistance is a critical factor.

- Strength and Ductility: 303 stainless steel possesses a good balance of strength and ductility. It exhibits high tensile strength, allowing it to withstand significant loads, and good ductility, enabling it to undergo plastic deformation without fracturing.

- Versatility: The combination of excellent machinability, corrosion resistance, strength, and ductility makes 303 stainless steel a versatile alloy suitable for a wide range of applications across various industries.

Disadvantages of Using Stainless Steel 303

- Limited Corrosion Resistance: While 303 stainless steel offers good corrosion resistance, it may not be suitable for highly corrosive environments or applications involving exposure to chloride-rich solutions. In such cases, other stainless steel grades with higher corrosion resistance, such as 316L, may be more appropriate.

- Lower Strength: Compared to some other stainless steel grades, 303 has a slightly lower tensile strength. This may limit its use in applications requiring extremely high strength.

- Cost: Due to the addition of alloying elements, such as nickel and chromium, stainless steel 303 can be more expensive than other carbon steels. However, its superior properties and performance often justify the higher cost.

Conclusion

Stainless steel 303 is a versatile alloy with excellent machinability, making it a preferred choice for many manufacturing applications. Its combination of corrosion resistance, strength, and ductility makes it suitable for a wide range of industries, from automotive and aerospace to medical and general engineering. By understanding the properties and applications of stainless steel 303, engineers and designers can make informed decisions to optimize their products and processes.

FAQ

What is the difference between stainless steel 303 and 304?

While both are austenitic stainless steels, 303 is specifically designed for superior machinability due to the addition of sulfur and phosphorus. 304, on the other hand, offers better corrosion resistance but is more difficult to machine.

Can stainless steel 303 be welded?

Yes, stainless steel 303 can be welded using appropriate welding techniques, such as TIG or MIG welding. However, it’s important to consider the potential loss of corrosion resistance in the weld area.

Is stainless steel 303 magnetic?

Yes, stainless steel 303 is magnetic, unlike some other stainless steel grades. This is due to its specific composition and the presence of certain elements.

What are the common heat treatments for stainless steel 303?

Stainless steel 303 is typically not heat-treated to improve its mechanical properties. However, it can be annealed to relieve stress and improve machinability.