Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100090063158454

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

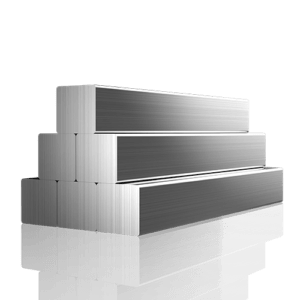

Stainless steel square tubing is a versatile and durable product that has become increasingly popular in various industries. Its unique combination of strength, corrosion resistance, and aesthetic appeal makes it an ideal choice for a wide range of applications, from construction and manufacturing to decorative and architectural projects. This comprehensive guide will delve into the properties, types, applications, and benefits of stainless steel square tubing, providing you with the information you need to make informed decisions about its use.

Understanding Stainless Steel Square Tubing

Stainless steel square tubing is a hollow, square-shaped profile made from stainless steel. It is known for its exceptional strength, durability, corrosion resistance, and aesthetic appeal. These properties make it an ideal choice for applications that require a combination of strength and style.

Composition and Grades

Stainless steel square tubing is available in various grades, each with unique characteristics. The most common grades include:

- Type 304: Offers a good balance of corrosion resistance and strength, making it suitable for general-purpose applications, such as construction, automotive, and food processing equipment.

- Type 316: Provides superior corrosion resistance, making it ideal for marine environments, chemical processing, and medical applications.

- Type 430: A magnetic grade with good corrosion resistance and formability, often used for decorative purposes, such as architectural cladding and furniture.

Benefits of Stainless Steel Square Tubing

Stainless steel square tubing offers numerous benefits that make it a preferred choice for many applications:

- Excellent Corrosion Resistance: Stainless steel’s inherent corrosion resistance makes it highly durable, especially in harsh environments such as coastal areas, industrial settings, and outdoor applications.

- Exceptional Strength and Durability: Stainless steel tubing is known for its high strength-to-weight ratio, making it capable of withstanding heavy loads and impact. This makes it ideal for structural applications, such as building frames and bridge components.

- Versatility: It can be easily fabricated and welded, allowing for a wide range of design possibilities. This versatility makes it suitable for various applications, from simple to complex structures.

- Aesthetic Appeal: Stainless steel’s sleek and modern appearance enhances the visual appeal of any project. Its polished or brushed finishes can add a touch of elegance to both interior and exterior designs.

- Hygienic: Stainless steel is easy to clean and sanitize, making it ideal for applications in the food processing, pharmaceutical, and medical industries. It is resistant to bacterial growth and can maintain a high level of hygiene.

Applications of Stainless Steel Square Tubing

Stainless steel square tubing finds applications in a diverse range of industries and sectors:

- Construction: Used for structural support, railings, handrails, architectural features, and cladding.

- Manufacturing: Employed in the production of equipment, machinery, and industrial components.

- Automotive: Used in the manufacturing of exhaust systems, roll cages, and other automotive parts.

- Furniture: Utilized to create stylish and durable furniture, such as tables, chairs, and shelving units.

- Decorative: Used for creating decorative elements, such as sculptures, railings, and cladding.

- Marine: Used in boat building, marine hardware, and other marine applications due to its excellent corrosion resistance.

Choosing the Right Stainless Steel Square Tubing

When selecting stainless steel square tubing for your project, consider the following factors:

- Grade: Choose a grade that is suitable for the specific application and environment. For example, Type 316 is ideal for marine environments, while Type 304 is suitable for general-purpose applications.

- Size: Select the appropriate size based on the required strength and load-bearing capacity. Consider the wall thickness and overall dimensions to ensure the tubing can withstand the intended loads.

- Finish: Choose a finish that complements the desired aesthetic and provides the necessary protection. Common finishes include polished, brushed, and mill finish.

- Tolerance: Specify the required tolerances to ensure a precise fit and accurate fabrication.

Fabrication and Installation

Stainless steel square tubing can be easily fabricated using various methods:

- Cutting: Can be cut using saws, plasma cutters, or laser cutters to achieve precise dimensions.

- Welding: Can be welded using various welding processes, such as TIG, MIG, and spot welding, to create strong and durable joints.

- Bending: Can be bent to create custom shapes and curves, adding flexibility to design possibilities.

Maintenance and Care

Stainless steel square tubing requires minimal maintenance to retain its appearance and performance:

- Regular Cleaning: Regular cleaning with mild detergent and water is usually sufficient to remove dirt and grime. Avoid using abrasive cleaners that can scratch the surface.

- Corrosion Protection: In harsh environments, consider applying a protective coating or sealant to further enhance corrosion resistance.

Comparison of Stainless Steel Square Tubing with Other Materials

| Feature | Stainless Steel Square Tubing | Aluminum Square Tubing | Carbon Steel Square Tubing |

|---|---|---|---|

| Corrosion resistance | Excellent | Good | Poor |

| Strength | High | Moderate | High |

| Weight | Moderate | Light | Heavy |

| Cost | Moderate to high | Low | Low |

| Welding | Easy | Easy | Easy |

Conclusion

Stainless steel square tubing is a versatile and durable material that offers a wide range of benefits. Its exceptional properties, including corrosion resistance, strength, and aesthetic appeal, make it an ideal choice for numerous industries and applications. By understanding the different grades, applications, and fabrication methods, you can make informed decisions about using stainless steel square tubing in your projects.

FAQ

What is the difference between stainless steel and carbon steel square tubing?

Stainless steel is alloyed with chromium, making it highly resistant to corrosion, while carbon steel is susceptible to rust.

Can stainless steel square tubing be welded?

Yes, stainless steel square tubing can be welded using various welding processes, such as TIG, MIG, and spot welding.

What is the best finish for stainless steel square tubing?

The best finish depends on the specific application and desired aesthetic. Common finishes include polished, brushed, and mill finish.