Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100090063158454

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

When it comes to construction, manufacturing, and engineering, the debate between steel vs stainless steel is one that has been ongoing for many years. Both materials have unique properties that make them suitable for various applications. However, understanding the differences between steel and stainless steel is essential when choosing the right material for your projects. This blog post will explore five key differences between steel vs stainless steel, shedding light on their composition, durability, resistance to corrosion, cost, and more.

Composition: Steel vs Stainless Steel

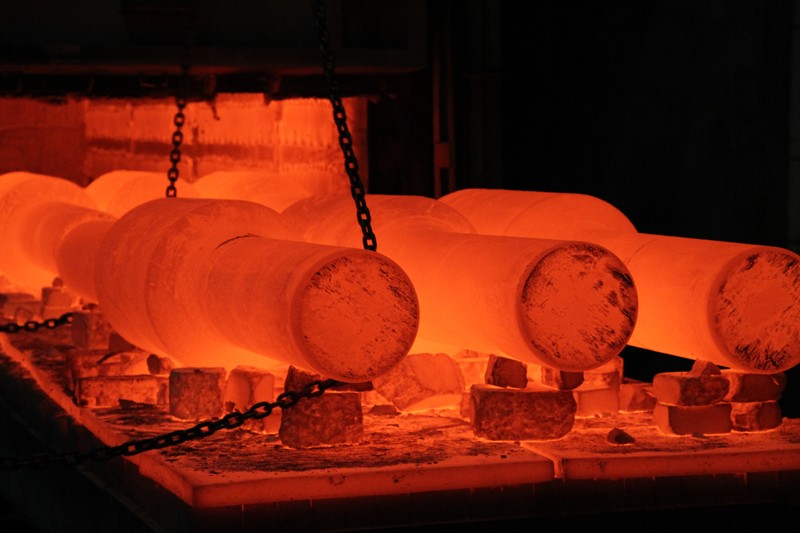

The first major difference between steel vs stainless steel lies in their composition. Steel is primarily made up of iron and carbon, with the addition of other elements in varying proportions. The carbon content in steel can range from low to high, which affects its strength, hardness, and flexibility.

On the other hand, stainless steel contains a significant amount of chromium, usually around 10.5% or higher. The presence of chromium gives stainless steel its corrosion-resistant properties. Stainless steel may also contain other elements like nickel and molybdenum, which further enhance its durability and resistance to rust and stains.

Durability: Steel vs Stainless Steel

Durability is a crucial factor when comparing steel vs stainless steel. While both materials are strong and versatile, stainless steel outshines steel in terms of long-term durability. Steel, depending on the type and carbon content, can be prone to rust and corrosion when exposed to moisture and certain environmental factors. This makes steel less suitable for outdoor or corrosive environments.

Stainless steel, however, is known for its superior resistance to rust and corrosion, even in harsh environments. The chromium content forms a protective layer on the surface, which helps to prevent oxidation and corrosion. This makes stainless steel ideal for applications where longevity and resistance to environmental factors are crucial.

Corrosion Resistance: Steel vs Stainless Steel

Corrosion resistance is a standout feature when comparing steel vs stainless steel. As mentioned earlier, the chromium in stainless steel forms a passive layer that protects the material from rust and corrosion. This property makes stainless steel highly desirable for industries such as food processing, medical equipment, and outdoor construction, where exposure to moisture and chemicals is common.

Steel, on the other hand, is more vulnerable to corrosion when exposed to water, oxygen, or chemicals. While certain types of steel, like galvanized steel, are coated to improve corrosion resistance, they still cannot match the level of protection that stainless steel naturally offers.

Cost: Steel vs Stainless Steel

When it comes to cost, steel is generally more affordable than stainless steel. The manufacturing process for steel is less complex and requires fewer raw materials compared to stainless steel. Additionally, steel is widely available, making it a more budget-friendly option for many applications.

Stainless steel, due to its higher chromium content and additional elements, is more expensive to produce. The added cost of stainless steel is reflected in its enhanced durability, corrosion resistance, and longer lifespan. For projects that require high-quality material with a longer service life, the higher cost of stainless steel may be justifiable.

Strength and Flexibility: Steel vs Stainless Steel

Both steel and stainless steel offer excellent strength, but their properties differ based on the specific type and use. Steel, depending on its carbon content, can be more flexible, making it easier to shape and weld. This makes it suitable for projects where flexibility and ease of processing are key factors.

Stainless steel, while also strong, tends to be less flexible due to its composition. The higher alloy content makes it more rigid, which can be a disadvantage in applications that require a material that is easy to manipulate. However, stainless steel’s strength-to-weight ratio is superior, which makes it ideal for applications where strength and corrosion resistance are more important than flexibility.

Table: Key Differences Between Steel vs Stainless Steel

| Property | Steel | Stainless Steel |

|---|---|---|

| Composition | Primarily iron and carbon | Iron, carbon, and chromium |

| Durability | Can rust over time | Highly durable and corrosion-resistant |

| Corrosion Resistance | Prone to rust | Naturally resistant to corrosion |

| Cost | Less expensive | More expensive |

| Strength and Flexibility | More flexible, easier to shape | Strong but less flexible |

Conclusion

In summary, when comparing steel vs stainless steel, the two materials have distinct differences that influence their suitability for various applications. Steel is more affordable and flexible, making it ideal for projects that require cost-efficiency and ease of shaping. However, stainless steel offers superior corrosion resistance, durability, and strength, making it the preferred choice for environments that demand high-quality, long-lasting materials. Understanding these key differences will help you make an informed decision when choosing between steel and stainless steel for your next project.

FAQ

Is stainless steel stronger than steel?

While stainless steel is strong, its flexibility is slightly lower than that of steel due to its higher alloy content. Stainless steel has better resistance to corrosion and tends to have a higher strength-to-weight ratio.

Why is stainless steel more expensive than steel?

Stainless steel is more expensive because it contains chromium and other alloys, which increase its production cost. These added elements enhance the material’s corrosion resistance and durability.

Can steel be used outdoors?

Steel can be used outdoors, but it may require coatings or treatments to prevent rust and corrosion. Stainless steel is a better option for outdoor applications due to its natural corrosion resistance.

What industries use stainless steel?

Stainless steel is commonly used in industries like food processing, medical equipment, construction, and chemical processing, where resistance to corrosion and longevity are essential.

How can I tell if a steel product is stainless steel?

One of the easiest ways to identify stainless steel is by its resistance to rust and corrosion. If the material shows signs of rusting or corrosion over time, it is likely steel rather than stainless steel.