Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100090063158454

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Introduction

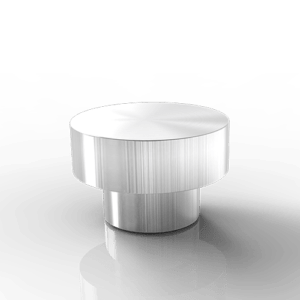

In today’s global manufacturing landscape, China stainless steel casting has emerged as a dominant force, offering a myriad of advantages that benefit various industries. As companies seek reliable and cost-effective solutions for their production needs, the advantages of utilizing stainless steel casting from China become increasingly evident. This article will explore the key benefits, applications, and technological advancements associated with China stainless steel casting, providing a comprehensive overview for industry professionals.

High-Quality Materials

One of the most significant advantages of China stainless steel casting is the high quality of materials used in production. Chinese manufacturers have made substantial investments in technology and quality control, ensuring that the stainless steel produced meets international standards.

Quality Control Processes

- Raw Material Selection: The use of high-grade stainless steel alloys ensures durability and resistance to corrosion.

- Certifications: Many manufacturers obtain certifications like ISO 9001, which assures customers of quality management practices.

- Testing Procedures: Rigorous testing methods, including chemical composition analysis and mechanical property testing, are standard practices.

Quality Control Steps in China Stainless Steel Casting

| Step | Description |

|---|---|

| Raw Material Inspection | Verifying quality of incoming materials |

| In-Process Testing | Continuous monitoring during the casting process |

| Final Product Testing | Comprehensive testing before shipment |

Cost-Effectiveness

Another compelling reason to consider China stainless steel casting is the cost-effectiveness of production. The combination of lower labor costs and economies of scale allows Chinese manufacturers to offer competitive pricing without compromising quality.

Factors Contributing to Cost-Effectiveness

- Labor Costs: Lower wages in China reduce overall production costs.

- Mass Production: The ability to produce large quantities efficiently leads to lower unit costs.

- Supply Chain Efficiency: A well-established supply chain minimizes delays and reduces costs.

Advanced Manufacturing Techniques

China is at the forefront of adopting advanced manufacturing technologies, enhancing the capabilities of stainless steel casting. Techniques such as 3D printing and computer-aided design (CAD) have revolutionized the industry.

Benefits of Advanced Techniques

- Precision: Enhanced accuracy in casting shapes and dimensions.

- Complex Designs: Ability to produce intricate and complex geometries that were previously difficult to achieve.

- Reduced Waste: Efficient use of materials leads to less waste and a more sustainable production process.

Advanced Techniques in China Stainless Steel Casting

| Technique | Description |

|---|---|

| 3D Printing | Rapid prototyping and custom designs |

| CAD Modeling | Detailed design plans for precision casting |

| Automated Inspection | Use of technology for quality assurance |

Versatility in Applications

The versatility of China stainless steel casting allows it to be used across a wide range of industries, including automotive, aerospace, medical, and construction. This adaptability is one of its key strengths.

Common Applications

- Automotive Parts: Engine components, exhaust systems, and other critical parts.

- Aerospace Components: Lightweight and durable parts for aircraft.

- Medical Equipment: Instruments and tools that require high hygiene standards.

Sustainability and Environmental Impact

As global awareness of environmental issues grows, the sustainability of manufacturing processes becomes increasingly important. China stainless steel casting is making strides toward more sustainable practices.

Sustainable Practices

- Recycling: Many manufacturers incorporate recycled materials into their casting processes.

- Energy Efficiency: Modern foundries use energy-efficient technologies to reduce their carbon footprint.

- Waste Management: Effective waste management systems minimize the environmental impact of production.

Sustainability Practices in China Stainless Steel Casting

| Practice | Description |

|---|---|

| Material Recycling | Use of recycled stainless steel in casting |

| Energy-Efficient Equipment | Investment in modern, energy-saving machinery |

| Waste Reduction Strategies | Methods to minimize waste during production |

Customization and Flexibility

One of the standout features of China stainless steel casting is the ability to provide customized solutions tailored to specific client needs. This flexibility is crucial in industries where unique specifications are often required.

Customization Options

- Design Modifications: Ability to adjust designs based on client requirements.

- Material Selection: Offering various stainless steel grades to suit different applications.

- Batch Size Flexibility: Capability to produce both small and large batches efficiently.

Conclusion

The advantages of China stainless steel casting are numerous and far-reaching. From high-quality materials and cost-effectiveness to advanced manufacturing techniques and sustainability, the benefits are clear for industries looking to enhance their production capabilities. As China continues to innovate and invest in its casting capabilities, businesses worldwide can expect to leverage these advantages to improve their operations and product quality.

FAQ

What is stainless steel casting?

Stainless steel casting is a manufacturing process that involves pouring molten stainless steel into a mold to create a desired shape.

Why choose China for stainless steel casting?

China offers a combination of high-quality materials, cost-effective production, advanced technology, and versatile applications.

How is the quality of China stainless steel casting ensured?

Quality is ensured through stringent quality control processes, including raw material inspection, in-process testing, and final product testing.

What industries benefit from stainless steel casting?

Industries such as automotive, aerospace, medical, and construction all benefit from the versatility and durability of stainless steel casting.

Are there sustainable practices in China stainless steel casting?

Yes, many manufacturers incorporate recycling, energy-efficient technologies, and waste management strategies to minimize environmental impact.