Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100090063158454

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Introduction

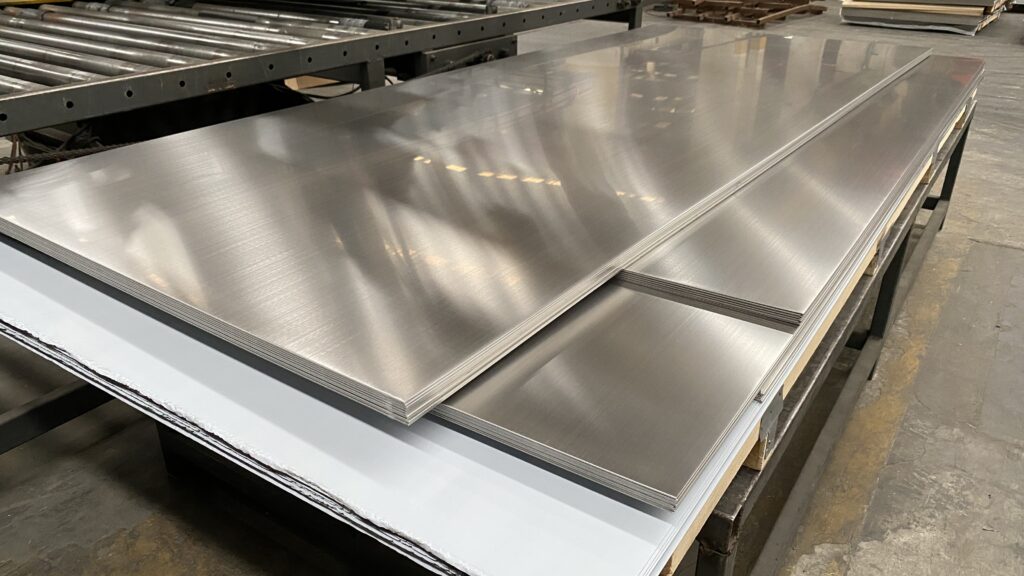

440 stainless steel is a high-carbon martensitic stainless steel known for its excellent hardness and resistance to wear and corrosion. In the manufacturing sector, it has become a popular choice for various applications due to its unique properties. This blog will explore the numerous benefits of 440 stainless steel in manufacturing, covering its applications, advantages, and reasons for its growing popularity in various industries.

Properties of 440 Stainless Steel

440 stainless steel is characterized by its unique composition, which typically includes around 16-18% chromium and 0.6-0.75% carbon. These elements provide a balance of strength, hardness, and corrosion resistance, making it suitable for many manufacturing processes.

Key Properties

| Property | Description |

|---|---|

| Hardness | Excellent hardness after heat treatment |

| Corrosion Resistance | Good resistance in various environments |

| Wear Resistance | High resistance to wear, suitable for cutting tools |

| Machinability | Fairly good machinability with proper tooling |

| Weldability | Limited; usually requires pre-heating |

Applications of 440 Stainless Steel

440 stainless steel is widely used in various applications due to its durability and performance. Below are some of the common uses in manufacturing:

1. Cutting Tools

One of the primary applications of 440 stainless steel is in the production of cutting tools such as knives, blades, and surgical instruments. Its hardness ensures that these tools maintain sharp edges and perform well over time.

2. Automotive Industry

In the automotive sector, 440 stainless steel is used for manufacturing components that require high strength and wear resistance. Applications include gears, valves, and various other engine components.

3. Aerospace Industry

The aerospace industry demands materials that can withstand extreme conditions. 440 stainless steel is utilized in parts that must resist corrosion while maintaining structural integrity.

4. Household Items

440 stainless steel is also common in household items like cutlery and kitchen tools. Its appealing finish and resistance to stains make it ideal for these applications.

Advantages of 440 Stainless Steel in Manufacturing

The benefits of using 440 stainless steel in manufacturing are numerous. Here are some of the key advantages:

1. High Strength and Hardness

440 stainless steel provides exceptional strength and hardness, making it suitable for demanding applications. This is particularly important in industries where durability is critical.

2. Corrosion Resistance

With its high chromium content, 440 stainless steel exhibits good resistance to corrosion, allowing it to perform well in harsh environments, including exposure to moisture and chemicals.

3. Wear Resistance

The material’s wear resistance makes it ideal for applications that involve friction or abrasion. Tools and components made from 440 stainless steel can endure prolonged use without significant wear.

4. Aesthetic Appeal

The shiny surface of 440 stainless steel not only enhances its visual appeal but also makes it easier to clean, which is essential in industries such as food and pharmaceuticals.

Comparison of 440 Stainless Steel with Other Alloys

Understanding how 440 stainless steel compares to other alloys can help manufacturers make informed decisions. Below is a simple table highlighting some differences:

| Alloy Type | Hardness | Corrosion Resistance | Typical Applications |

|---|---|---|---|

| 440 Stainless Steel | High | Good | Cutting tools, automotive parts |

| 304 Stainless Steel | Medium | Excellent | Kitchenware, chemical processing |

| 316 Stainless Steel | Medium | Superior | Marine applications, medical devices |

Conclusion

440 stainless steel has established itself as a valuable material in the manufacturing industry. Its high hardness, corrosion resistance, and wear resistance make it suitable for a wide range of applications. As manufacturers seek materials that can endure harsh conditions while maintaining performance, 440 stainless steel will continue to play a crucial role in various sectors.

FAQ

What is 440 stainless steel used for?

440 stainless steel is primarily used in cutting tools, automotive components, aerospace applications, and household items like cutlery.

How does 440 stainless steel compare to other stainless steels?

440 stainless steel offers high hardness and good wear resistance compared to other stainless steels, but its corrosion resistance is lower than that of alloys like 316 stainless steel.

Can 440 stainless steel be welded?

While it can be welded, it is recommended to preheat it to avoid cracking. Post-weld heat treatment is also advisable to restore its properties.

Is 440 stainless steel magnetic?

Yes, 440 stainless steel is magnetic due to its martensitic structure, making it different from austenitic stainless steels like 304 or 316.

How should I maintain 440 stainless steel?

Regular cleaning with mild soap and water, followed by drying, will help maintain its appearance and performance. Avoid abrasive cleaners that can scratch the surface.

By understanding the benefits of 440 stainless steel, manufacturers can leverage its unique properties to enhance their products and processes, ensuring quality and durability across various applications.