Introduction

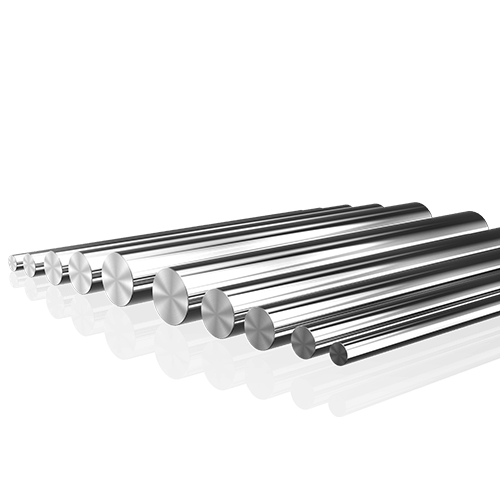

In the realm of metallurgy, the 316 stainless steel round bar stands out as a pinnacle of durability and versatility. This alloy, primarily composed of iron, chromium, nickel, and molybdenum, offers a myriad of applications across industries due to its exceptional corrosion resistance, strength, and formability. In this comprehensive exploration, we delve into the remarkable attributes of the 316 stainless steel round bar, elucidating its chemical composition, mechanical properties, diverse applications, and environmental sustainability.

Chemical Composition and Properties

The composition of 316 stainless steel round bar is meticulously crafted to imbue it with unparalleled characteristics. With a minimum of 10% nickel content, this alloy exhibits superior corrosion resistance, making it ideal for applications in harsh environments such as marine and chemical processing. Additionally, the presence of molybdenum enhances its resistance to pitting and crevice corrosion, further extending its lifespan.

Mechanical Properties

The mechanical properties of 316 stainless steel round bar underscore its suitability for a wide array of industrial applications. Its high tensile strength, coupled with excellent creep and stress-rupture strengths, makes it indispensable in structural components subjected to heavy loads and high temperatures. Moreover, its exceptional ductility facilitates ease of fabrication, enabling the creation of intricate designs without sacrificing structural integrity.

Applications

The versatility of 316 stainless steel round bar knows no bounds, finding applications across diverse industries:

- Marine Industry: From shipbuilding to offshore platforms, 316 stainless steel round bar is the material of choice due to its unparalleled resistance to corrosion from seawater and harsh marine environments.

- Chemical Processing: In chemical plants where corrosive substances abound, 316 stainless steel round bar ensures the longevity of critical components such as valves, pipes, and storage tanks.

- Medical Devices: Its biocompatibility and resistance to sterilization methods make it indispensable in the manufacture of surgical instruments, implants, and medical equipment.

- Food and Beverage Industry: Compliance with stringent hygiene standards and resistance to food acids and chemicals make 316 stainless steel round bar the preferred material for food processing equipment and storage vessels.

- Architectural Applications: Its aesthetic appeal, coupled with durability and low maintenance requirements, render it an ideal choice for architectural elements such as handrails, facade panels, and decorative features.

Environmental Sustainability

The sustainability of 316 stainless steel round bar lies not only in its longevity and recyclability but also in its contribution to energy efficiency. Its durability translates to extended service life, reducing the frequency of replacements and conserving resources. Furthermore, its recyclability at the end of its lifecycle minimizes waste and lowers the carbon footprint of industries reliant on this alloy.

Below is a breakdown of the chemical composition of 316 stainless steel round bar:

| Element | Composition (%) |

|---|---|

| Iron (Fe) | 65.0-74.0 |

| Chromium | 16.0-18.0 |

| Nickel | 10.0-14.0 |

| Molybdenum | 2.0-3.0 |

| Carbon | ≤0.08 |

| Silicon | ≤1.00 |

| Manganese | ≤2.00 |

| Phosphorus | ≤0.045 |

| Sulfur | ≤0.03 |

Conclusion

In conclusion, the 316 stainless steel round bar emerges as a quintessential material, embodying the perfect synergy of durability, versatility, and sustainability. Its exceptional corrosion resistance, mechanical properties, and diverse applications make it indispensable across industries, from marine and chemical processing to healthcare and architecture. As we continue to innovate and engineer new materials, the enduring legacy of 316 stainless steel round bar remains unchallenged, symbolizing the pinnacle of metallurgical achievement.

FAQ

Q: Is 316 stainless steel round bar suitable for outdoor applications?

A: Yes, its superior corrosion resistance makes it ideal for outdoor use, even in harsh environmental conditions.

Q: Can 316 stainless steel round bar be welded?

A: Yes, it can be welded using standard welding techniques, although precautions must be taken to avoid sensitization and intergranular corrosion.

Q: How does 316 stainless steel round bar compare to other stainless steel alloys?

A: Compared to other stainless steel alloys, 316 offers superior corrosion resistance, particularly in chloride environments, thanks to its higher nickel and molybdenum content.

Q: Is 316 stainless steel round bar magnetic?

A: No, it is typically non-magnetic in its annealed state but may become slightly magnetic after cold working.