Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100090063158454

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Introduction

When it comes to construction, manufacturing, or various industrial applications, choosing the right stainless steel fabricators is crucial. Stainless steel offers numerous advantages, including corrosion resistance, strength, and versatility. However, not all fabricators are created equal. This article will guide you through the key factors to consider when selecting stainless steel fabricators, ensuring you make an informed choice that meets your specific needs.

Understanding Stainless Steel Fabricators

What are Stainless Steel Fabricators?

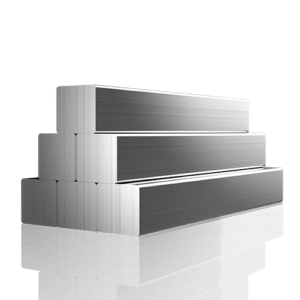

Stainless steel fabricators are companies that specialize in transforming raw stainless steel into finished products. This process includes cutting, bending, welding, and assembling steel components for various applications, ranging from architectural features to industrial equipment.

The Importance of Quality Fabrication

The quality of fabrication directly affects the durability and functionality of the final product. Poorly executed fabrication can lead to structural failures and increased maintenance costs, making it essential to choose a reputable fabricator.

Key Factors to Consider

Experience and Expertise

The first factor to consider is the experience of the stainless steel fabricators. Look for companies with a proven track record in the industry. Experienced fabricators will have a better understanding of the complexities involved in working with stainless steel and can offer valuable insights.

Quality of Materials

The quality of the stainless steel used is another critical aspect. Not all stainless steel is created equal; different grades have different properties and applications. Inquire about the types of stainless steel that the fabricators work with and ensure they meet industry standards.

Range of Services Offered

Different projects require different services. Some fabricators may specialize in specific areas such as custom fabrication, while others offer a more comprehensive range of services. Evaluate the services offered and ensure they align with your project requirements.

Technology and Equipment

Modern technology plays a vital role in the quality of fabrication. Ensure the fabricators use state-of-the-art machinery and techniques. This not only improves efficiency but also enhances the precision of the final products.

Certifications and Standards

Certifications can provide insight into a fabricator’s commitment to quality and safety. Look for fabricators that comply with industry standards such as ISO certifications or ASME codes. These certifications indicate a higher level of professionalism and quality assurance.

Customer Reviews and Testimonials

One of the best ways to gauge the reliability of stainless steel fabricators is through customer reviews. Look for testimonials or case studies that highlight previous projects. Positive feedback from past clients can give you confidence in your choice.

Pricing and Value

While cost should not be the sole determining factor, it is essential to consider pricing in the context of the value offered. Compare quotes from different fabricators, but also weigh the quality of materials and services provided.

Table of Essential Factors

| Factor | Importance | Considerations |

|---|---|---|

| Experience | High | Look for years in business and past projects |

| Quality of Materials | Critical | Ask about steel grades and sourcing |

| Range of Services | Medium | Ensure they meet specific project needs |

| Technology and Equipment | High | Check for modern machinery and capabilities |

| Certifications | High | Verify compliance with industry standards |

| Customer Reviews | Medium | Research testimonials and feedback |

| Pricing | Medium | Compare costs relative to services offered |

The Fabrication Process

Steps in Stainless Steel Fabrication

Understanding the fabrication process can help you communicate your needs more effectively. Here’s a brief overview of the steps involved:

- Design and Engineering: Initial plans are created based on specifications.

- Material Selection: Choosing the appropriate grade and type of stainless steel.

- Cutting and Bending: Utilizing machinery to cut and shape the steel.

- Welding and Assembly: Joining components through welding techniques.

- Finishing Touches: Surface finishing, such as polishing or coating, to enhance durability.

Common Applications of Stainless Steel Fabrication

Stainless steel fabricators cater to various industries, including:

- Architecture: Handrails, facades, and decorative elements.

- Food and Beverage: Equipment like tanks, conveyors, and countertops.

- Automotive: Exhaust systems, frames, and various components.

- Manufacturing: Custom parts for machinery and industrial applications.

Evaluating Potential Fabricators

Site Visits and Consultations

Before making a final decision, consider visiting the fabricators’ facilities. This allows you to assess their operations firsthand and ask questions directly. A site visit can provide valuable insights into their capabilities and commitment to quality.

Asking the Right Questions

Prepare a list of questions to ask potential fabricators. Here are some examples:

- What types of stainless steel do you work with?

- Can you provide references from previous clients?

- What is your typical lead time for projects?

- How do you ensure quality control during fabrication?

Conclusion

Choosing the right stainless steel fabricators is a critical step in ensuring the success of your project. By considering factors such as experience, quality of materials, range of services, and customer feedback, you can make an informed decision. Take the time to research and evaluate your options, and you’ll find a fabricator that aligns with your needs and standards.

FAQ

What is the difference between various grades of stainless steel?

Different grades of stainless steel offer varying levels of corrosion resistance, strength, and ductility. The most common grades include 304 and 316, with 316 providing better corrosion resistance.

How long does the fabrication process take?

The timeline can vary based on the complexity of the project and the fabricator’s workload. Typically, smaller projects may take a few weeks, while larger ones can take several months.

Can stainless steel be recycled?

Yes, stainless steel is highly recyclable and can be reused without compromising its properties, making it an environmentally friendly option.

What should I look for in a quote from a stainless steel fabricators?

When reviewing quotes, consider the breakdown of costs, materials used, lead times, and any warranties or guarantees offered.