Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100090063158454

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Introduction

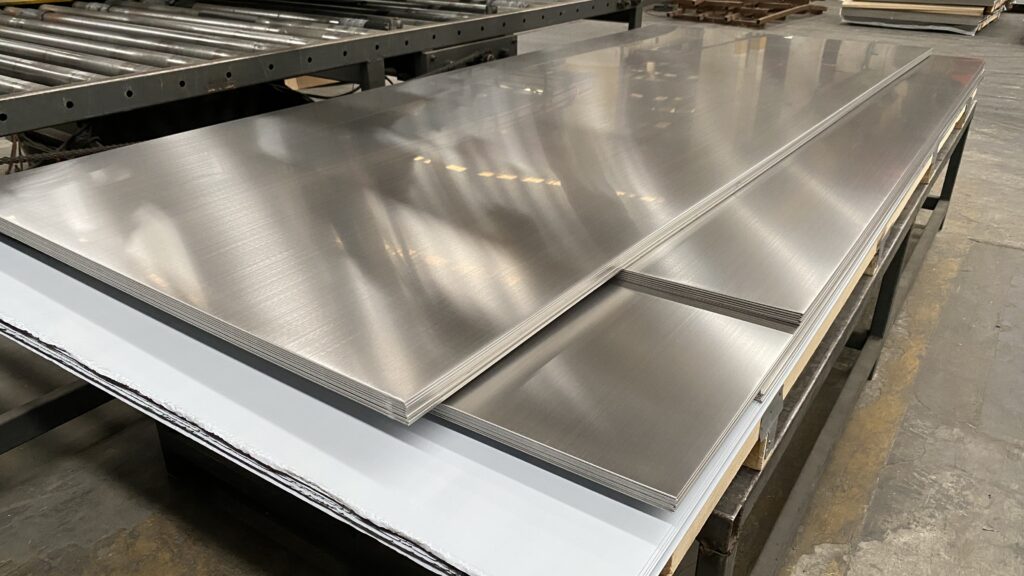

When it comes to industrial-grade materials, 316 stainless steel composition stands out for its durability, corrosion resistance, and broad application scope. This article provides an in-depth look at the 316 stainless steel composition, including its elements, benefits, common uses, and comparison with other stainless steels. Understanding the 316 stainless steel composition is essential for selecting the right material for various industries, from medical devices to marine applications.

Table of Contents

- The Basics of 316 Stainless Steel Composition

- Key Components of 316 Stainless Steel

- Benefits of 316 Stainless Steel Composition

- 316 vs. 304 Stainless Steel: Understanding the Difference

- Common Applications of 316 Stainless Steel

- Detailed Analysis of Corrosion Resistance

- Frequently Asked Questions (FAQ)

- Conclusion

1. The Basics of 316 Stainless Steel Composition

316 stainless steel, often called marine-grade stainless steel, is widely known for its high corrosion resistance. The 316 stainless steel composition contains chromium, nickel, and molybdenum, which collectively strengthen its resistance to various chemicals and environmental conditions. These components work together to improve the performance of 316 stainless steel in various demanding environments, including high-salt and high-moisture conditions.

| Element | Percentage (%) |

|---|---|

| Chromium | 16-18 |

| Nickel | 10-14 |

| Molybdenum | 2-3 |

| Carbon | ≤ 0.08 |

| Manganese | ≤ 2.0 |

| Silicon | ≤ 0.75 |

| Phosphorus | ≤ 0.045 |

| Sulfur | ≤ 0.03 |

| Nitrogen | ≤ 0.10 |

The 316 stainless steel composition provides resilience and enhanced resistance, making it a favored choice for marine, chemical, and medical applications.

2. Key Components of 316 Stainless Steel

Each element in 316 stainless steel composition plays a unique role in enhancing its characteristics:

- Chromium (16-18%): Improves corrosion resistance by forming a protective oxide layer.

- Nickel (10-14%): Enhances ductility and resistance to extreme temperatures.

- Molybdenum (2-3%): Significantly boosts resistance to pitting and crevice corrosion in chloride environments.

- Carbon (≤ 0.08%): Keeps the steel malleable while maintaining its strength.

Together, these elements make the 316 stainless steel composition ideal for applications demanding high durability, corrosion resistance, and exposure to chemicals.

3. Benefits of 316 Stainless Steel Composition

The 316 stainless steel composition brings various benefits, including:

- High Corrosion Resistance: Especially effective in saltwater and acidic environments due to its molybdenum content.

- Increased Strength and Durability: Resists wear and tear better than other stainless steels.

- Heat Resistance: Performs well in high-temperature settings, allowing it to be used in a variety of industrial applications.

- Ease of Fabrication: Despite its strength, 316 stainless steel can be easily welded and fabricated.

These attributes make the 316 stainless steel composition suitable for extreme environments, including marine, chemical, and high-temperature applications.

4. 316 vs. 304 Stainless Steel: Understanding the Difference

The primary difference between 316 stainless steel composition and 304 is the presence of molybdenum in 316. This difference significantly affects their performance:

| Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Molybdenum Content | Absent | 2-3% |

| Corrosion Resistance | Good | Superior, especially in saltwater |

| Cost | Lower | Higher due to molybdenum addition |

| Applications | General, kitchenware | Marine, chemical, medical devices |

While both grades are highly resistant to corrosion, 316 stainless steel composition is especially beneficial in harsh environments, such as coastal and chemical-processing settings.

5. Common Applications of 316 Stainless Steel

Thanks to its superior 316 stainless steel composition, this alloy is used in diverse industries, including:

- Marine Industry: Suitable for ship components, docks, and other marine equipment.

- Medical Devices: Utilized in surgical instruments and implants due to biocompatibility.

- Chemical Processing: Resistant to harsh chemicals, making it suitable for equipment in the chemical industry.

- Food and Beverage: Common in food processing equipment, offering easy sanitation and resistance to acid exposure.

The versatility of 316 stainless steel composition continues to make it a reliable choice across many sectors.

6. Detailed Analysis of Corrosion Resistance

One of the most valuable aspects of 316 stainless steel composition is its ability to resist corrosion, even in extreme environments. Molybdenum, an essential component, helps prevent corrosion from chlorides, acids, and alkalis. The chromium in the alloy also plays a critical role, forming a passive layer that blocks oxidation. This layer regenerates if damaged, ensuring that the stainless steel remains protected from rust and corrosion over time.

| Corrosion Type | Resistance Level in 316 Stainless Steel |

|---|---|

| General Corrosion | Excellent |

| Pitting and Crevice Corrosion | Very Good |

| Stress Corrosion Cracking | Good |

| Intergranular Corrosion | Good |

The 316 stainless steel composition provides an ideal balance of corrosion protection across different types, ensuring long-lasting material integrity.

7. Frequently Asked Questions (FAQ)

Q1: What is the main difference in composition between 316 and 304 stainless steel?

A1: The main difference is the presence of molybdenum in 316 stainless steel, which enhances corrosion resistance, particularly against chloride and acidic environments.

Q2: Can 316 stainless steel withstand high temperatures?

A2: Yes, the 316 stainless steel composition is known for good heat resistance, making it ideal for high-temperature applications.

Q3: Is 316 stainless steel magnetic?

A3: No, due to its high nickel content, 316 stainless steel is generally non-magnetic.

Q4: Why is 316 stainless steel more expensive than 304?

A4: The cost is higher due to the molybdenum content, which enhances its corrosion resistance, particularly in challenging environments.

Q5: What makes 316 stainless steel suitable for medical applications?

A5: The 316 stainless steel composition offers excellent biocompatibility and is resistant to bodily fluids, making it a popular choice for surgical tools and implants.

Conclusion

Understanding 316 stainless steel composition provides insight into why it is such a popular and valuable material across various industries. Its unique balance of corrosion resistance, strength, and adaptability makes it a preferred choice for challenging environments, from deep-sea applications to medical devices. The 316 stainless steel composition demonstrates how alloying elements like chromium, nickel, and molybdenum work together to enhance durability and longevity, ensuring that 316 stainless steel remains a trusted material for engineers and manufacturers worldwide.