Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100090063158454

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

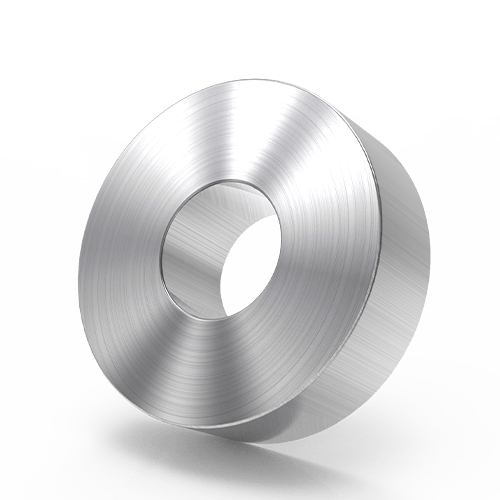

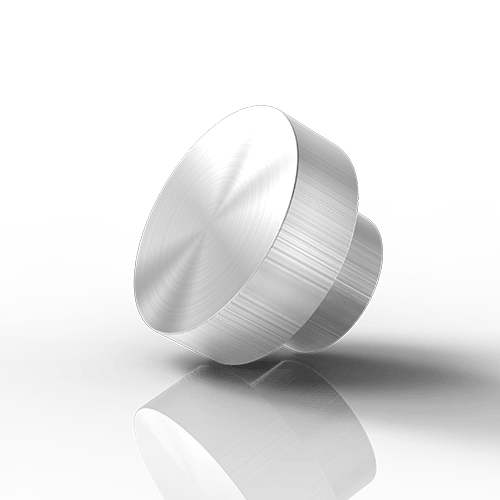

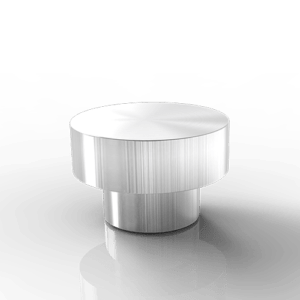

Choosing the right 316 stainless steel tube manufacturer is essential for ensuring the structural integrity and functionality of the tubes. These tubes are used in various applications such as chemical processing, marine environments, and medical devices, where reliability is crucial. Low-quality manufacturing processes or materials can result in premature failure, corrosion, or reduced performance.

The Role of 316 Stainless Steel Tube Manufacturers in Ensuring Quality

316 stainless steel tubes are known for their exceptional resistance to corrosion, especially in harsh environments like saltwater or high-temperature conditions. However, not all manufacturers produce tubes of the same quality. A reliable 316 stainless steel tube manufacturer must adhere to stringent quality control standards to ensure that the finished product meets the required specifications. This includes selecting high-grade raw materials, using advanced production techniques, and conducting thorough testing throughout the manufacturing process.

Key Factors That Influence the Quality of 316 Stainless Steel Tubes

Raw Materials

The quality of raw materials directly affects the final product’s strength, durability, and resistance to corrosion. Top-tier 316 stainless steel manufacturers source high-quality steel from trusted suppliers to ensure the best performance.

Manufacturing Processes

The production techniques employed by manufacturers play a crucial role in the final quality of the tubes. Advanced methods such as precision welding, cold working, and annealing are commonly used to improve tube strength and uniformity.

Quality Control and Testing

Comprehensive quality control and testing processes are essential for ensuring that each batch of tubes meets industry standards. Tests such as tensile strength, hardness, and corrosion resistance tests are conducted to verify product performance.

Customization and Precision

Customization allows 316 stainless steel tubes to be tailored to specific requirements, such as dimensions, wall thickness, and surface finish. A high-quality manufacturer can meet these demands with precision and consistency.

Benefits of Choosing High-Quality 316 Stainless Steel Tube Manufacturers

When you choose a reputable and quality-focused 316 stainless steel tube manufacturer, you benefit from:

Longer Lifespan

High-quality tubes are less likely to experience premature failure or degradation, resulting in a longer lifespan for your equipment and systems.

Reduced Maintenance Costs

With superior corrosion resistance and mechanical properties, high-quality 316 stainless steel tubes require less maintenance, saving you time and money in the long run.

Improved Performance

316 stainless steel tubes manufactured to exact specifications deliver better overall performance, ensuring that your projects run smoothly without unexpected delays or complications.Compliance with Industry Standards

Quality manufacturers ensure their products meet or exceed industry standards, helping you stay compliant with safety regulations and certifications.

Comparison Table: Top Features of Leading 316 Stainless Steel Tube Manufacturers

| Manufacturer Feature | High-Quality 316 Stainless Steel Tubes | Low-Quality 316 Stainless Steel Tubes |

|---|---|---|

| Material Quality | Premium raw materials with high corrosion resistance | Inferior raw materials prone to degradation |

| Manufacturing Processes | Precision welding, cold working, and annealing | Basic manufacturing processes without fine-tuning |

| Customization | Custom sizes, finishes, and specifications available | Limited customization options |

| Quality Control | Rigorous testing for strength, hardness, and corrosion resistance | Minimal testing or quality checks |

| Certifications | Meets or exceeds industry standards and certifications | May lack necessary certifications |

How to Identify High-Quality 316 Stainless Steel Tube Manufacturers

Finding the right manufacturer can be challenging, but here are a few tips for identifying a quality supplier:

Check Certifications and Standards

Reputable manufacturers will have certifications such as ISO 9001, which signifies adherence to international quality management standards. They will also comply with ASTM A312 and other relevant specifications for 316 stainless steel tubes.

Review Customer Testimonials and Case Studies

Customer feedback is one of the best ways to gauge a manufacturer’s reliability and product quality. Look for case studies and testimonials from industries that require high-performance materials.

Ask About Their Quality Control Process

A trusted manufacturer will be transparent about their quality control procedures and testing protocols. Inquire about how they ensure product consistency and performance.

Evaluate Their Manufacturing Capabilities

High-quality manufacturers invest in advanced technologies and machinery. Ensure they have the capability to meet your specific requirements, such as customized dimensions and finishes.

Conclusion: Why You Should Prioritize Quality with 316 Stainless Steel Tube Manufacturers

In conclusion, choosing a high-quality 316 stainless steel tube manufacturer is essential for ensuring the durability, performance, and reliability of the tubes. By working with a manufacturer that adheres to rigorous quality control standards, you can avoid costly repairs, maintenance, and downtime. Prioritize quality to ensure that your projects meet industry requirements, stay within budget, and deliver superior results.

FAQ

Why is 316 stainless steel better than other types of stainless steel?

316 stainless steel offers superior corrosion resistance, particularly in chloride-rich environments like seawater, making it ideal for marine, medical, and chemical applications.

How can I tell if the 316 stainless steel tube manufacturer I’m considering is reliable?

Look for certifications, customer reviews, and details about their manufacturing processes. A reliable manufacturer will be transparent about their quality control methods and industry compliance

What are the common applications for 316 stainless steel tubes?

316 stainless steel tubes are commonly used in marine environments, chemical processing, food processing, medical devices, and heat exchangers due to their excellent corrosion resistance and durability